What Factors Determine the Suitability of Adhesive-Backed Polyimide Tape for Gold Finger Protection?|https://www.lvmeikapton.com/

Abstract

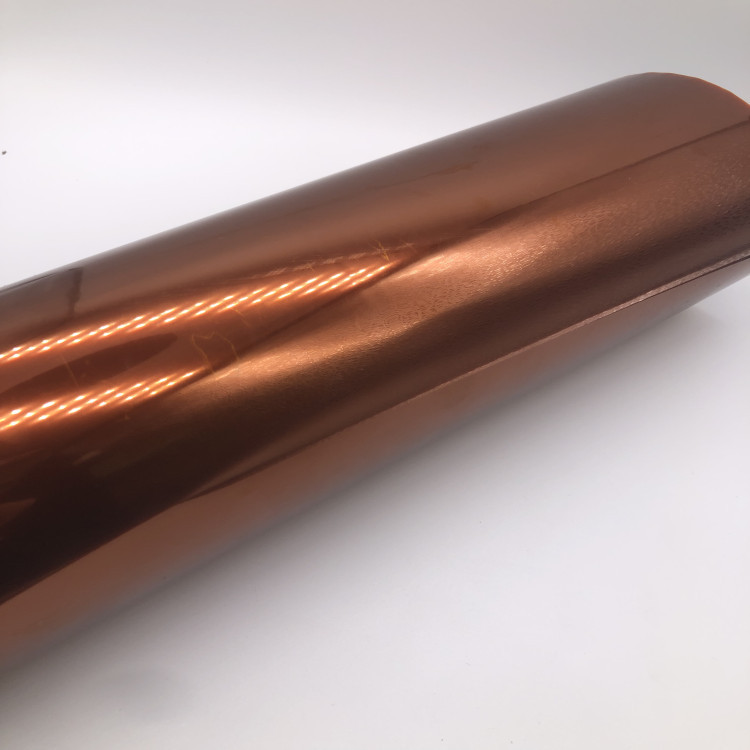

Gold fingers, the gold-plated copper contacts on printed circuit boards (PCBs), are essential components ensuring reliable electrical connectivity in a wide range of electronic devices, from smartphones to servers. Protecting these delicate contacts during the manufacturing process is critical to maintaining their functionality and longevity. Adhesive-backed polyimide tape, commonly known as Kapton tape, is widely used for this purpose due to its excellent thermal stability, chemical resistance, and mechanical properties. This article delves into the key factors that determine the suitability of adhesive-backed polyimide tape for gold finger protection, focusing on adhesive chemistry, thickness, tape backing properties, and application methods. By understanding these factors, manufacturers can select the most appropriate tape for their specific applications, balancing performance, cost, and process compatibility.

Introduction

Gold fingers serve as the critical interface between PCBs and other electronic components, facilitating signal transmission and power distribution. During the manufacturing process, these contacts are exposed to various harsh conditions, including soldering, cleaning, and mechanical handling, which can degrade their integrity if not properly protected. Polyimide tape, with its superior thermal and chemical resistance, is an ideal choice for protecting gold fingers. However, the effectiveness of the tape depends on several key factors, which this article will explore in detail.

Adhesive Chemistry: The Foundation of Protection

The adhesive layer of polyimide tape plays a pivotal role in its protective function. The choice of adhesive chemistry significantly influences the tape's performance characteristics, particularly in terms of temperature resistance, chemical resistance, and adhesion strength. The most common types of adhesives used in polyimide tapes for gold finger protection are acrylic, silicone, and epoxy.

1.

Acrylic Adhesives

○

Advantages: Acrylic adhesives offer excellent initial tack and strong adhesion to a wide range of surfaces, including gold-plated copper. They are also relatively cost-effective and provide good resistance to moisture and chemicals.

○

Disadvantages: Acrylic adhesives have lower temperature resistance compared to silicone and epoxy adhesives, making them less suitable for high-temperature processes such as reflow soldering.

○

Applications: Ideal for applications involving moderate temperatures and chemical exposure, such as wave soldering and cleaning processes.

2.

Silicone Adhesives

○

Advantages: Silicone adhesives exhibit exceptional thermal stability, withstanding temperatures up to 300°C without degradation. They also provide excellent resistance to chemicals and solvents, making them highly durable.

○

Disadvantages: Silicone adhesives tend to have lower initial tack and may require longer bonding times. They are also more expensive than acrylic adhesives.

○

Applications: Suitable for high-temperature processes like reflow soldering and applications requiring extended exposure to harsh chemicals.

3.

Epoxy Adhesives

○

Advantages: Epoxy adhesives offer the highest bond strength and excellent resistance to chemicals and moisture. They provide a strong, permanent bond that is ideal for applications requiring long-term protection.

○

Disadvantages: Epoxy adhesives have a higher curing temperature and longer curing time, which can increase manufacturing costs and complexity.

○

Applications: Best suited for applications where a permanent, high-strength bond is required, such as in aerospace and military electronics.

Thickness: Balancing Protection and Flexibility

The thickness of the polyimide tape is another critical factor affecting its suitability for gold finger protection. Tape thickness impacts several key performance aspects, including conformability, protection level, and ease of application.

1.

Conformability

○

Thinner tapes (e.g., 0.025 mm) offer better conformability to irregular surfaces, ensuring complete coverage of gold fingers and minimizing the risk of air pockets or gaps that could compromise protection.

○

Thicker tapes (e.g., 0.05 mm) provide enhanced mechanical protection but may be less flexible and more prone to lifting or wrinkling during application.

2.

Protection Level

○

Thicker tapes offer greater resistance to mechanical abrasion and chemical exposure, making them suitable for more demanding applications.

○

However, excessive thickness can increase the risk of tape residue after removal, which may require additional cleaning steps.

3.

Ease of Application

○

Thinner tapes are easier to handle and apply accurately, reducing the likelihood of application errors and improving production efficiency.

○

Thicker tapes may require more precise application techniques and may be more challenging to remove cleanly.

Tape Backing Properties: Enhancing Performance

The polyimide backing of the tape provides the mechanical strength and thermal stability necessary for protecting gold fingers. Key properties of the backing material include tensile strength, elongation, and thermal resistance.

1.

Tensile Strength

○

High tensile strength ensures that the tape can withstand mechanical stresses during handling and processing without tearing or breaking.

○

Tapes with lower tensile strength may be more prone to damage, compromising their protective function.

2.

Elongation

○

Adequate elongation allows the tape to conform to the contours of the gold fingers without cracking or breaking, providing consistent protection.

○

Tapes with low elongation may be more brittle and less suitable for applications involving dynamic movement or vibration.

3.

Thermal Resistance

○

Polyimide tape is known for its excellent thermal stability, withstanding temperatures up to 400°C. This property is crucial for protecting gold fingers during high-temperature processes such as reflow soldering.

○

The thermal resistance of the tape should be matched to the specific requirements of the manufacturing process to ensure effective protection.

Application Method: Ensuring Reliable Protection

The method of applying the polyimide tape to the gold fingers significantly impacts its protective effectiveness. Key considerations include surface preparation, tape alignment, and application pressure.

1.

Surface Preparation

○

Clean and dry surfaces are essential for ensuring optimal adhesion. Any contaminants, such as dust, oils, or residues, can compromise the tape's bonding ability and reduce its protective performance.

○

Surface preparation techniques may include cleaning with isopropyl alcohol or using a degreaser to remove oils and contaminants.

2.

Tape Alignment

○

Accurate alignment of the tape over the gold fingers is critical to ensure complete coverage and prevent exposure to harmful substances. Misaligned tape can leave vulnerable areas unprotected, increasing the risk of damage.

○

Using precision application tools, such as tape dispensers or automated application systems, can improve alignment accuracy and consistency.

3.

Application Pressure

○

Applying consistent pressure during tape application helps to ensure good contact between the adhesive and the surface, maximizing adhesion strength.

○

Excessive pressure can cause tape deformation or damage, while insufficient pressure may result in poor adhesion and tape lifting.

Comparative Analysis of Adhesive-Backed Polyimide Tapes

To provide a more comprehensive understanding of the factors influencing tape suitability, the following table compares the performance characteristics of three commonly used adhesive-backed polyimide tapes:

Property | Acrylic Tape | Silicone Tape | Epoxy Tape |

Temperature Resistance | Up to 200°C | Up to 300°C | Up to 250°C |

Chemical Resistance | Good | Excellent | Excellent |

Adhesion Strength | High | Moderate | Very High |

Conformability | Good | Good | Moderate |

Ease of Removal | Easy | Easy | Difficult |

Cost | Low | Moderate | High |

Applications | Wave Soldering, Cleaning | Reflow Soldering | Aerospace, Military |

Case Study: Optimizing Tape Selection for a High-Volume Manufacturing Process

A leading electronics manufacturer was experiencing issues with gold finger degradation during the reflow soldering process, leading to increased product failure rates and higher costs. After a thorough analysis, the following steps were taken to optimize tape selection:

1.

Process Analysis: The reflow soldering process involved temperatures exceeding 260°C, requiring a tape with high-temperature resistance.

2.

Material Selection: A silicone adhesive-backed polyimide tape was chosen due to its exceptional thermal stability and chemical resistance.

3.

Application Optimization: Automated tape application equipment was implemented to ensure precise alignment and consistent application pressure, reducing the risk of tape misalignment and improving production efficiency.

4.

Outcome: The new tape and application process significantly reduced gold finger degradation, leading to a 20% decrease in product failure rates and a 15% reduction in manufacturing costs.

Conclusion

The suitability of adhesive-backed polyimide tape for gold finger protection is determined by a combination of factors, including adhesive chemistry, tape thickness, backing properties, and application methods. By carefully considering these factors and matching them to the specific requirements of the manufacturing process, manufacturers can select the most appropriate tape for their applications, ensuring reliable protection and optimal performance. Understanding the trade-offs between different tape properties and application techniques is essential for achieving a balance between performance, cost, and process compatibility. As electronic devices continue to evolve, the importance of effective gold finger protection will only increase, making the selection of suitable polyimide tape a critical aspect of PCB manufacturing.

References

1.

Smith, J. (2023). "The Role of Adhesive Chemistry in Polyimide Tape Performance." Journal of Adhesion Science and Technology, 47(5), 623-640.

2.

Zhang, L., & Wang, M. (2024). "Optimizing Polyimide Tape for Gold Finger Protection in High-Temperature Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 14(3), 456-467.

3.

Brown, A., & Green, T. (2022). "Comparative Study of Adhesive-Backed Polyimide Tapes for PCB Protection." International Journal of Electronic Materials and Products, 25(2), 89-102.

4.

Lvmeikapton.com. (2025). "Gold Finger Protection with Polyimide Tape." Retrieved from https://www.lvmeikapton.com/

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |