hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

What Makes Kapton Polyimide Tape Essential for Gold Finger Electronics? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-10-23

|

41 Views

|

Share:

The global electronics industry relies on precision, durability, and reliability—qualities embodied in gold finger connectors and the protective materials that safeguard them. When clients tour Hunan Lvzhimei New Material Technology Co., Ltd in Changsha, a frequent question arises: What makes Kapton polyimide tape essential for gold finger electronics? This article explores the scientific, industrial, and practical reasons behind this indispensable relationship.

What Makes Kapton Polyimide Tape Essential for Gold Finger Electronics? |https://www.lvmeikapton.com/

The global electronics industry relies on precision, durability, and reliability—qualities embodied in gold finger connectors and the protective materials that safeguard them. When clients tour Hunan Lvzhimei New Material Technology Co., Ltd in Changsha, a frequent question arises: What makes Kapton polyimide tape essential for gold finger electronics? This article explores the scientific, industrial, and practical reasons behind this indispensable relationship.

Understanding the Gold Finger ChallengeGold fingers are exposed PCB edges plated with gold to ensure optimal conductivity. However, they are vulnerable during assembly: high-temperature soldering can tarnish the gold, flux residues can corrode contacts, and handling may cause micro-scratches. Protection is not optional—it’s mandatory. This is where polyimide tape becomes essential.

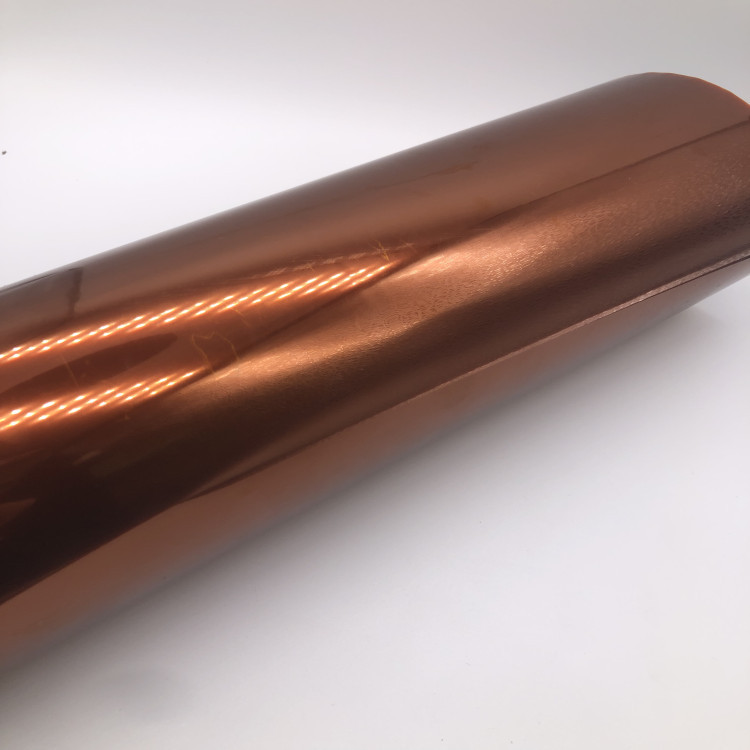

Kapton: The Material of ChoiceKapton polyimide film possesses a unique combination of properties:

●

Thermal Resistance: Withstands reflow soldering temperatures (up to 360°C) without degrading.

●

Chemical Inertness: Resists acids, solvents, and fluxes used in PCB manufacturing.

●

Mechanical Toughness: Maintains integrity under pressure and vibration.

●

Dielectric Strength: Prevents short circuits during high-voltage testing.

These attributes make Kapton-based polyimide tape the gold standard (pun intended) for protecting gold fingers.

Hunan Lvzhimei’s Value-Added EngineeringWhile raw Kapton film is impressive, its performance depends on formulation and processing. Our Changsha facility specializes in:

●

Adhesive Optimization: We use heat-resistant silicone adhesives that bond securely but release cleanly—critical for post-soldering removal.

●

Thickness Customization: Offering tapes from 25μm to 125μm to match client specifications.

●

Slitting and Die-Cutting: High-precision equipment produces tapes in exact widths and shapes, reducing labor and improving yield.

During client visits, we conduct peel strength tests, thermal cycling, and electrical insulation checks to validate performance.

Real-World Applications and Industry ImpactOur tapes are used by leading manufacturers in:

●

Consumer Electronics: Protecting connectors in smartphones, laptops, and gaming consoles.

●

Industrial Automation: Ensuring reliability in PLCs and motor controllers.

●

Aerospace & Defense: Where failure is not an option, our tapes guard mission-critical avionics.

One client from Germany shared how our tape reduced their PCB defect rate by 40%—a testament to its essential role.

Why Not Alternatives?Some consider PTFE or PET tapes, but they fall short: PTFE lacks adhesion, PET deforms under heat. Kapton remains unmatched. Hunan Lvzhimei further enhances it with anti-fog coatings and UV markers for traceability.

Sustainability and ComplianceWe ensure all tapes meet international standards (IPC-CC-830B, UL 510). Our production lines are energy-efficient, and we recycle off-cuts into secondary products.

In essence, Kapton polyimide tape is essential because it solves multiple challenges in one: protection, reliability, and process efficiency. At Hunan Lvzhimei, we don’t just supply tape—we deliver assurance.

.jpg)

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT