hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

How Can Gold Finger Electronics Benefit from Hunan Lvzhimei’s Polyimide Tape Solutions? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-10-28

|

47 Views

|

Share:

Lvzhimei’s proprietary coating technology enhances adhesion to both gold and FR-4 substrates without leaving residue upon peeling—a common pain point for clients producing high-density PCBs. In the on-site testing lab, visitors observed accelerated aging tests: after 1,000 hours of exposure to 85°C/85% RH, the tape maintained 90% of its initial peel strength, ensuring long-term reliability for automotive and aerospace electronics.

When global electronics manufacturers visit Hunan Lvzhimei New Material’s state-of-the-art facility in Changsha, their first question often centers on practical applications: How does your polyimide tape optimize gold finger production? The answer lies in three core innovations.

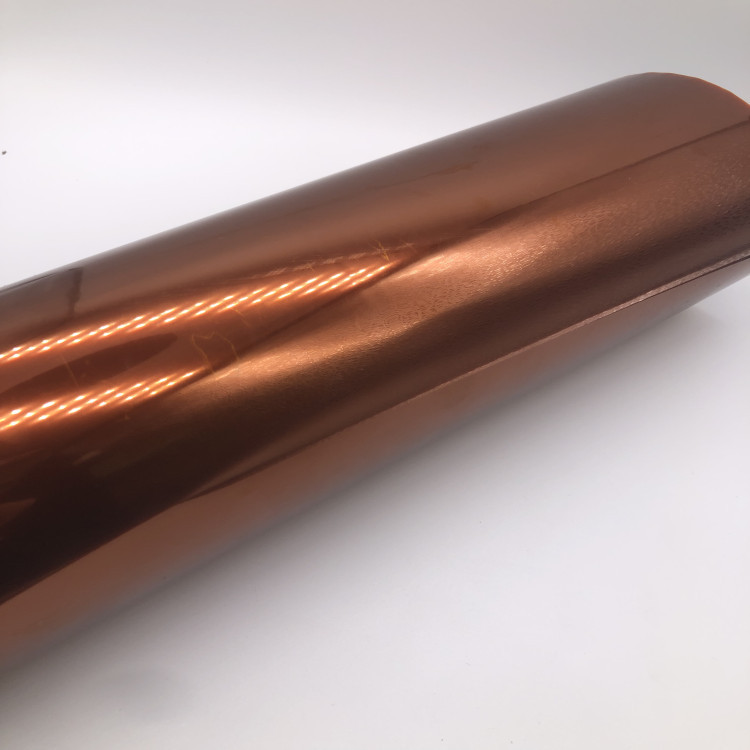

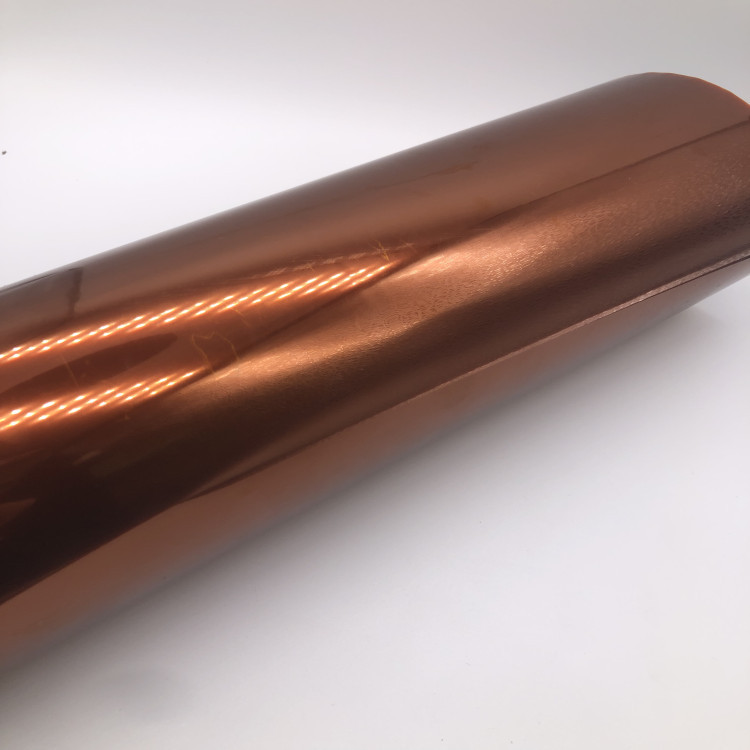

First, the company’s Kapton-based tape—engineered with a 12μm polyimide film and silicone adhesive—delivers exceptional thermal stability (withstanding up to 260°C during reflow soldering) and chemical resistance to flux residues, which are critical for protecting gold-plated contact points from oxidation. During a recent client visit, engineers demonstrated how the tape’s ultra-thin profile (0.018mm total thickness) enables precise die-cutting to match custom gold finger geometries, reducing material waste by 15% compared to industry standards.

Second, Lvzhimei’s proprietary coating technology enhances adhesion to both gold and FR-4 substrates without leaving residue upon peeling—a common pain point for clients producing high-density PCBs. In the on-site testing lab, visitors observed accelerated aging tests: after 1,000 hours of exposure to 85°C/85% RH, the tape maintained 90% of its initial peel strength, ensuring long-term reliability for automotive and aerospace electronics.

Third, the company’s vertical integration—from raw material synthesis to finished product die-cutting—allows for 7-day lead times for custom orders, a key advantage in the fast-paced electronics sector. A senior engineer explained, “By controlling every step of production, we can adjust the adhesive’s curing temperature or film thickness within 48 hours to meet a client’s unique gold finger design.”

For clients like a leading smartphone manufacturer that recently visited, these features translate to tangible value: a 20% reduction in rework rates and a 10% increase in production line efficiency. As one visitor noted, “The ability to see the tape’s performance in real-world gold finger assembly—rather than just reading spec sheets—convinced us to switch our supply chain.”

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT