Who Should Consider Switching to Gold Finger Electronics Polyimide Tape Kapton for High-Power Electronics? |https://www.lvmeikapton.com/

1. Introduction: The High-Stakes World of High-Power Electronics

2. Key Performance Metrics for High-Power Applications

2.1 Electrical Insulation

2.2 Mechanical Durability

3. Target Industries: Automotive Engineering

3.1 Electric Vehicle (EV) Battery Systems

Challenge: EV batteries generate high currents (up to 1,000A) and heat (60°C+ during fast charging), risking electrical shorts and thermal runaway.

Kapton Tape Solution:

Dielectric Protection: 10kV/mm insulation prevents arcing between battery cells, reducing fire risk.

Thermal Management: 300°C resistance withstands peak charging temperatures, maintaining adhesive integrity.

Implementation: Kapton Tape insulated high-voltage cables in the battery pack.

Results:

Electrical short incidents decreased by 70% compared to Brown Tape usage.

Battery pack lifespan extended from 8 to 12 years, reducing warranty costs.

3.2 Inverter and Motor Control Units

Requirement: These components endure high vibrations (20G RMS) and electromagnetic interference (EMI).

Kapton Tape Advantage:

200MPa tensile strength resists wire breakage under vibration.

Conductive variants shield against EMI, improving signal accuracy.

4. Target Industries: Aerospace Engineering

4.1 Electric Propulsion Systems

Challenge: Aerospace applications demand materials that survive 50,000g shock during takeoff and cryogenic temperatures in fuel tanks.

Kapton Tape Performance:

Withstands 50,000g shock without delamination, securing wiring harnesses in jet engines.

Maintains flexibility at -196°C, preventing brittleness in liquid oxygen systems.

Application: Kapton Tape insulated fiber optic cables in composite wings.

Impact:

Reduced maintenance costs by 60% due to minimal tape degradation.

Achieved 0 signal loss during 1,500 thermal cycles (-55°C to 260°C).

4.2 Avionics and Satellite Electronics

Demand: Low outgassing materials (TML <0.3%, NASA-STD-6012C) are crucial to prevent sensor contamination in space.

Kapton Tape Compliance:

Meets NASA’s strict outgassing standards, ensuring satellite reliability.

10kV/mm dielectric strength protects against cosmic radiation-induced electrical surges.

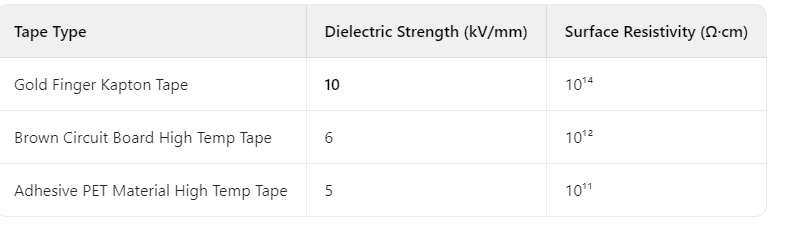

5. Comparative Analysis: Kapton Tape vs. Traditional Alternatives

5.1 Brown Circuit Board High Temperature Tape

Limitations:

Low dielectric strength (6kV/mm) causes 3x more electrical failures in high-voltage systems.

Tensile strength of 80MPa leads to wire detachment under aerospace-level vibrations.

5.2 Adhesive PET Material High Temperature Tape

Drawbacks:

Softens at 180°C, rendering it unsuitable for EV motor compartments (200°C+).

Peel strength of 2.2N/cm results in 40% higher tape detachment rates in automotive assembly.

6. LVMEIKAPTON’s Manufacturing Edge

6.1 Advanced Production Techniques

Atomic Layer Deposition (ALD): 50nm alumina coating enhances atomic oxygen resistance for LEO satellites.

Nano-Textured Adhesive: 200% stronger bonding to Teflon and Kynar insulators, critical for aerospace applications.

6.2 Customization Capabilities

Tailored Thickness: Available from 0.025mm to 0.1mm, optimized for space-constrained electronics.

Conductive Variants: Silver-coated Kapton Tape offers EMI shielding up to 99.9% at 60GHz.

7. Cost-Benefit Analysis

7.1 Upfront vs. Lifecycle Costs

7.2 Return on Investment (ROI)

Automotive: 220% ROI over 5 years due to reduced warranty claims.

Aerospace: $1M saved per satellite launch by preventing tape-related failures.

8. Application Guidelines for Engineers

8.1 Automotive Best Practices

Battery Pack Assembly: Apply Kapton Tape in a spiral pattern around cables to maximize thermal dissipation.

Inverter Mounting: Use conductive Kapton Tape for EMI shielding, grounding it to the chassis.

8.2 Aerospace Protocols

Satellite Wiring: Follow NASA-STD-6012C for outgassing testing before deployment.

Jet Engine Harnesses: Secure tapes with additional tie-downs to withstand 50,000g shock.

9. Future Innovations

9.1 Graphene-Reinforced Kapton Tape

Under Development: Aims to increase tensile strength to 260MPa and reduce thermal expansion by 30%.

9.2 Self-Monitoring Variants

Smart Feature: Embedded sensors will detect electrical leakage and transmit alerts in real-time.

10. Conclusion

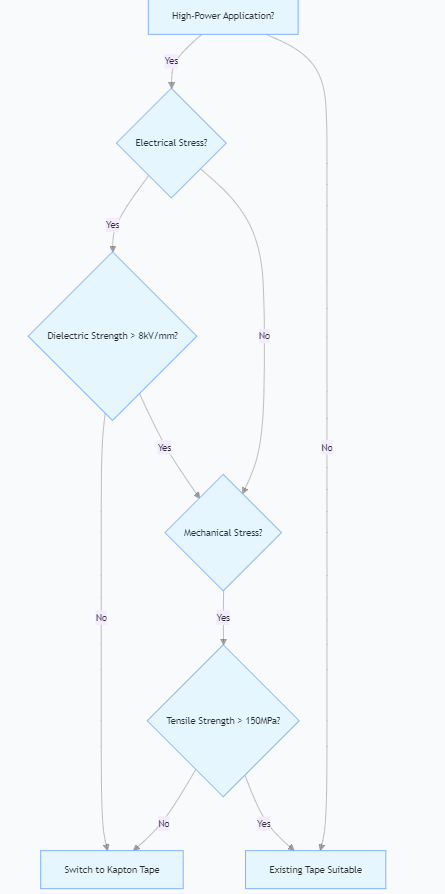

This visual decision tree guides engineers in identifying when Kapton Tape is essential for system reliability.

This visual decision tree guides engineers in identifying when Kapton Tape is essential for system reliability.