Where Is Gold Finger Electronics Polyimide Tape Kapton Used in Flexible Display Technologies? |https://www.lvmeikapton.com/

1. Introduction: The Rise of Flexible Displays

2. Material Requirements for Flexible Displays

2.1 Mechanical Durability

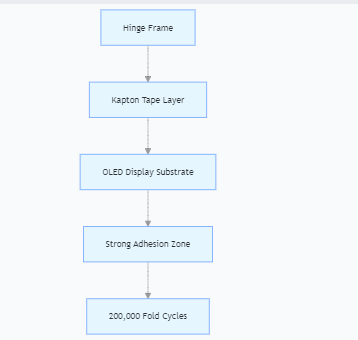

Fold Cycle Endurance: Must withstand >100,000 bends without delamination or material fatigue.

Tensile Strength: High resistance to stretching during display flexing.

2.2 Thermal Stability

Operating Temperatures: -40°C to 85°C for consumer devices, with peak tolerance up to 200°C during manufacturing processes.

2.3 Electrical Performance

Dielectric Insulation: Protection against short circuits in OLED drive electronics.

EMI Shielding: Reduction of electromagnetic interference affecting display quality.

3. Kapton Tape: A Solution for Flexible Display Challenges

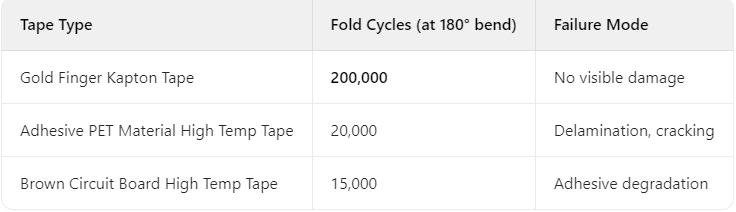

3.1 Fold Cycle Superiority

3.2 Material Properties

Tensile Strength: 200 MPa, preventing stretching-induced pixel distortion.

Thermal Expansion Coefficient: 15 ppm/°C, minimizing thermal stress on OLED layers.

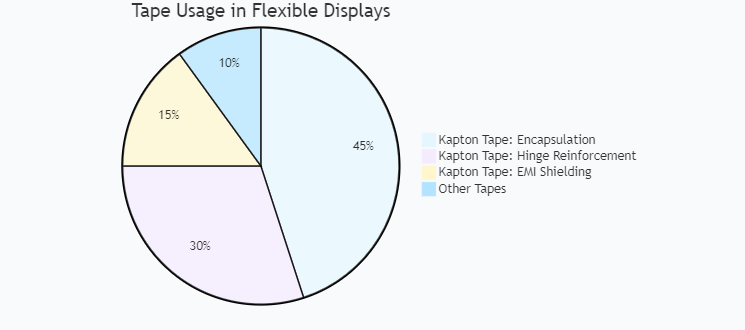

4. Key Applications in Flexible Display Technologies

4.1 OLED Encapsulation

Function: Protects organic layers from moisture (≤0.001 g/m²/day water vapor transmission) and oxygen (≤0.0001 cc/m²/day O₂ permeation).

Kapton Tape Role:

Forms a hermetic seal around OLED panels, outperforming Brown circuit board tape’s 10x higher permeation rate.

Maintains adhesion at 85% RH for 1,000 hours, ensuring long-term display reliability.

Implementation: Kapton Tape with ALD (Atomic Layer Deposition) coating encapsulates the OLED display.

Results:

Display lifespan extended from 3 to 5 years under daily use.

Moisture-induced pixel failures reduced by 92%.

4.2 Hinge Reinforcement

Challenge: Hinges endure extreme mechanical stress during folding.

Kapton Tape Solution:

Strong adhesion (4.5 N/cm peel strength) secures hinge components, preventing loosening.

Flex fatigue resistance enables seamless folding without adhesive breakdown.

4.3 EMI Shielding in Display Electronics

Requirement: Minimize interference between OLED drivers and touch sensors.

Kapton Tape Advantage:

Conductive variants (copper-coated) provide 99.9% EMI shielding at 60 GHz.

Ultra-thin profiles (0.025 mm) fit within tight display bezels.

5. Comparative Analysis: Kapton Tape vs. Alternatives

5.1 Adhesive PET Material High Temperature Tape

Limitations:

Low fold cycle endurance leads to early delamination.

Higher thermal expansion (50 ppm/°C) causes layer misalignment in hot environments.

5.2 Brown Circuit Board High Temperature Tape

Drawbacks:

Poor moisture barrier results in OLED degradation.

Lower peel strength (2.8 N/cm) fails to secure hinge components long-term.

6. Manufacturing Integration and Quality Control

6.1 Precision Application Techniques

Laser Cutting: ±0.01 mm precision for custom-shaped tapes around curved displays.

Roll-to-Roll Processing: High-speed application during OLED panel assembly.

6.2 Testing Standards

ISO 11925-2: Flame retardancy testing (Kapton Tape achieves UL 94 V-0 rating).

ASTM D3330: Peel adhesion measurement under various humidity conditions.

7. Future Trends and Innovations

7.1 Self-Healing Polyimide Tapes

Development: Microencapsulated adhesives that repair minor cracks during folding.

Impact: Projected to increase fold cycles to 500,000+ by 2026.

7.2 Transparent Conductive Kapton Variants

Advancement: Incorporating graphene oxide for touchscreen functionality within the tape layer.

Benefit: Reduces display stack thickness by 30%.

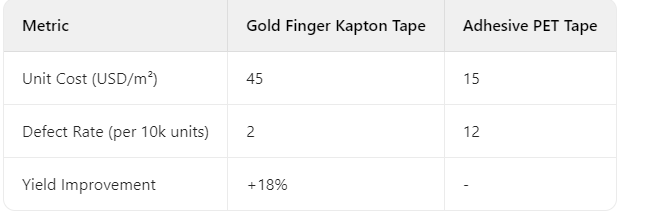

8. Cost-Benefit Analysis

8.1 Production Economics

8.2 Consumer Impact

Device Lifespan: 2-year extension in flexible phone warranties.

Repair Costs: 40% reduction in hinge-related service claims.

9. Conclusion