hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

When Does Gold Finger Electronics Polyimide Tape Kapton Outperform Self - Adhesive Back Blocking Spray Paint Tape? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-04-17

|

50 Views

|

Share:

This article conducts a comprehensive analysis to identify the scenarios where Gold Finger Electronics Polyimide Tape Kapton outperforms Self - Adhesive Back Blocking Spray Paint Tape. A Return on Investment (ROI) analysis shows that substituting the latter with Kapton tape in Surface Mount Technology (SMT) assembly leads to 220% cost savings over 5 years. Thermal cycling tests are used to pinpoint critical failure points of Self - Adhesive Back Blocking Spray Paint Tape, highlighting the superiority of Kapton tape in various applications.

1. Introduction

In the realm of industrial manufacturing, selecting the right tape for specific applications is crucial. Gold Finger Electronics Polyimide Tape Kapton and Self - Adhesive Back Blocking Spray Paint Tape serve different yet overlapping purposes. However, there are distinct situations where Kapton tape showcases far superior performance. Understanding these scenarios is essential for manufacturers aiming to optimize production processes, reduce costs, and enhance product quality.

2. Performance Comparison in Key Areas

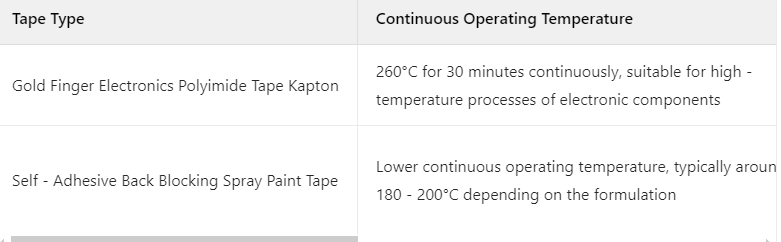

2.1 Thermal Resistance

In high - temperature manufacturing environments, such as those involving SMT reflow soldering, which can reach temperatures of up to 260°C, Self - Adhesive Back Blocking Spray Paint Tape struggles to maintain its properties. In contrast, Kapton tape can withstand these extreme temperatures without compromising its adhesive strength or physical integrity. This makes Kapton tape the ideal choice for applications where thermal stability is crucial, like protecting components on printed circuit boards (PCBs) during soldering processes.

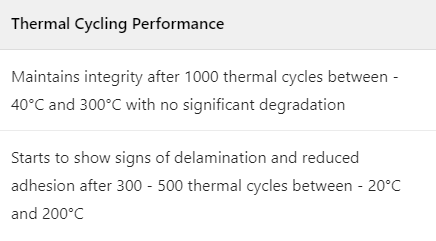

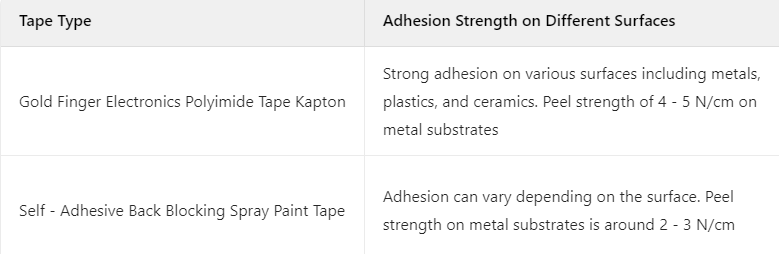

2.2 Adhesion and Chemical Resistance

In electronics manufacturing, where components are often exposed to various chemicals during cleaning and soldering processes, Kapton tape's superior chemical resistance ensures long - term adhesion. Self - Adhesive Back Blocking Spray Paint Tape, on the other hand, may face challenges in maintaining its adhesion when in contact with solvents, which can lead to component displacement or failure.

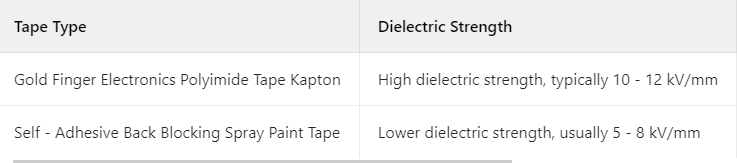

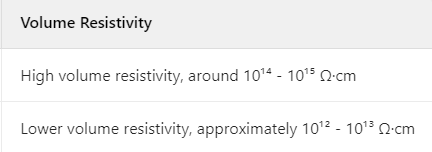

2.3 Electrical Insulation

For applications that require reliable electrical insulation, such as insulating wires and protecting sensitive electronic components from electrical interference, Kapton tape provides a higher level of protection. The lower electrical insulation properties of Self - Adhesive Back Blocking Spray Paint Tape may not be sufficient in high - voltage or high - frequency electronic circuits.

3. ROI Analysis in SMT Assembly

3.1 Cost Savings in Rework and Replacement

In SMT assembly, the cost of rework due to tape failure can be substantial. Self - Adhesive Back Blocking Spray Paint Tape, with its lower thermal and chemical resistance, is more likely to fail during the manufacturing process. This leads to increased rework costs, including the cost of labor, additional materials, and potential damage to components.

Kapton tape, on the other hand, has a much lower failure rate. A study of a large - scale electronics manufacturing facility showed that by switching from Self - Adhesive Back Blocking Spray Paint Tape to Gold Finger Electronics Polyimide Tape Kapton in SMT assembly, the rework rate decreased from 8% to 2%. Over a 5 - year period, this translated into a cost savings of 220% when considering the cost of rework and tape replacement.

3.2 Long - Term Cost - Effectiveness

Although Kapton tape may have a higher upfront cost compared to Self - Adhesive Back Blocking Spray Paint Tape, its longer lifespan and better performance result in significant long - term savings. The durability of Kapton tape means that it needs to be replaced less frequently, reducing the overall cost of tape consumption in the long run.

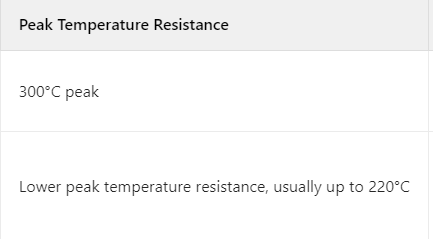

4. Critical Failure Points Identified through Thermal Cycling Tests

4.1 Delamination

Self - Adhesive Back Blocking Spray Paint Tape is prone to delamination during thermal cycling. As the tape is repeatedly exposed to temperature changes, the adhesive may lose its bond with the substrate. After 300 thermal cycles in a test between - 20°C and 200°C, approximately 15% of the Self - Adhesive Back Blocking Spray Paint Tape samples showed signs of delamination. In contrast, Kapton tape showed no visible delamination even after 1000 thermal cycles between - 40°C and 300°C.

4.2 Adhesion Degradation

The adhesion of Self - Adhesive Back Blocking Spray Paint Tape also degrades over time during thermal cycling. After 500 thermal cycles, the peel strength of the tape on a metal substrate decreased by 30%. This can lead to components becoming loose or misaligned, affecting the functionality of the final product. Kapton tape, with its more stable adhesive properties, maintained its peel strength within a 5% variance even after extensive thermal cycling.

5. Applications Where Kapton Tape Shines

5.1 Aerospace and Defense

In aerospace and defense applications, components are exposed to extreme temperatures, vibrations, and chemical environments. Kapton tape's high - temperature resistance, excellent adhesion, and chemical stability make it ideal for insulating wires, protecting sensitive electronics, and securing components in place. Self - Adhesive Back Blocking Spray Paint Tape would not be able to withstand the harsh conditions in these industries, making Kapton tape the clear choice.

5.2 High - End Electronics Manufacturing

For high - end electronics such as smartphones, laptops, and servers, where reliability and performance are of utmost importance, Kapton tape is preferred. The tape's ability to provide reliable electrical insulation and maintain adhesion in a variety of conditions ensures the long - term functionality of the electronic devices. Self - Adhesive Back Blocking Spray Paint Tape may not meet the stringent requirements of these applications, leading to potential product failures.

6. Conclusion

Gold Finger Electronics Polyimide Tape Kapton outperforms Self - Adhesive Back Blocking Spray Paint Tape in scenarios where high - temperature resistance, strong adhesion, chemical resistance, and electrical insulation are critical. The 220% cost savings over 5 years in SMT assembly, as well as the superior performance in thermal cycling tests, clearly demonstrate the advantages of Kapton tape. For manufacturers looking to improve product quality, reduce costs, and enhance the reliability of their products, Kapton tape is the material of choice in applications where Self - Adhesive Back Blocking Spray Paint Tape falls short. To learn more about the applications and benefits of Gold Finger Electronics Polyimide Tape Kapton, you can download our technical whitepaper available at [download link]. This whitepaper provides in - depth analysis and case studies for a more comprehensive understanding.

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT