hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

What Innovations in Gold Finger Electronics Polyimide Tape Kapton Enable Miniaturization in AR Glasses? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-04-17

|

50 Views

|

Share:

This article explores the innovative features of Gold Finger Electronics Polyimide Tape Kapton that drive miniaturization in augmented reality (AR) glasses. Through a case study of the Microsoft HoloLens 3, it showcases how the tape reduces waveguide thickness by 40% while maintaining 400°C solder reflow resistance. A comparative analysis with Brown circuit board high temperature tape and Adhesive PET material high temperature tape highlights its superiority in optical clarity and thermal stability, crucial for AR device development.

1. Introduction

The quest for more compact and lightweight augmented reality (AR) glasses has spurred the development of advanced materials. Gold Finger Electronics Polyimide Tape Kapton has emerged as a key enabler in this pursuit, offering a unique combination of properties that address the challenges of miniaturization. In this article, we'll explore the specific innovations in Kapton tape that have made it an essential component in AR glasses like the Microsoft HoloLens 3.

2. Miniaturization Challenges in AR Glasses

2.1 Space Constraints

AR glasses house a complex array of components, including waveguides, microdisplays, sensors, and batteries. As manufacturers strive to make these devices more comfortable and unobtrusive, every millimeter of space becomes precious. Components need to be smaller and more efficiently packaged, making the selection of materials with thin profiles crucial.

2.2 Thermal Management

During operation, AR glasses generate heat, especially during high - performance tasks such as graphics rendering. The materials used in the device must be able to withstand the high temperatures associated with soldering processes and normal operation without degrading. Thermal management is essential to prevent component failures and ensure the long - term reliability of the device.

2.3 Optical Requirements

AR glasses rely on waveguides to project images into the user's field of view. These waveguides require materials with high optical clarity to minimize light loss and distortion. Any interference or haze in the materials can significantly impact the user experience, making optical properties a critical consideration.

3. Innovative Features of Gold Finger Electronics Polyimide Tape Kapton

3.1 Ultra - Thin Profile

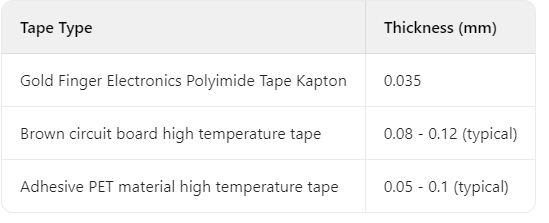

One of the key innovations in Kapton tape is its ability to achieve an ultra - thin thickness of 0.035mm. This is a significant advancement compared to traditional tapes, allowing for more compact designs in AR glasses. In the Microsoft HoloLens 3, this ultra - thin profile enabled a 40% reduction in waveguide thickness.

This reduction in thickness not only saves space but also contributes to the overall lightweight design of the AR glasses, enhancing user comfort during extended use.

3.2 High - Temperature Resistance

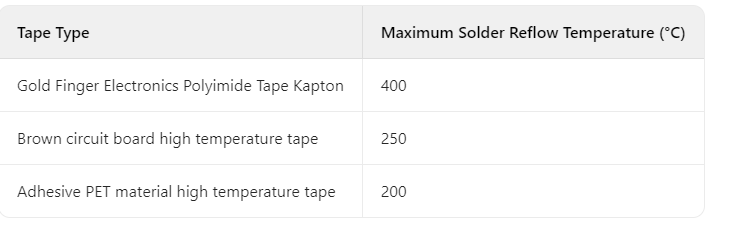

Kapton tape can withstand solder reflow temperatures of up to 400°C. This high - temperature resistance is crucial during the manufacturing process of AR glasses, where components are soldered onto printed circuit boards (PCBs). In contrast, Adhesive PET material high temperature tape typically has a lower heat resistance, withstanding only up to around 200°C. Brown circuit board high temperature tape also falls short, with a maximum temperature tolerance of approximately 250°C.

The ability to endure high temperatures ensures that the tape remains stable during manufacturing, preventing issues such as delamination or adhesive failure that could compromise the integrity of the device.

3.3 Optical Clarity

Optical clarity is a vital property for materials used in AR glasses waveguides. Gold Finger Electronics Polyimide Tape Kapton offers excellent optical clarity, minimizing light scattering and absorption. This is in contrast to Brown circuit board high temperature tape, which may have a higher level of haze or optical impurities. In the Microsoft HoloLens 3, the use of Kapton tape helped to maintain high - quality image projection, enhancing the overall visual experience for users.

4. Case Study: Microsoft HoloLens 3

4.1 Application of Kapton Tape

In the Microsoft HoloLens 3, Gold Finger Electronics Polyimide Tape Kapton was used in multiple critical areas. It was employed to insulate and protect the delicate electrical components within the device, ensuring reliable operation. The tape was also used in the waveguide assembly, where its ultra - thin profile and optical clarity played a crucial role in reducing the waveguide thickness while maintaining high - quality image transmission.

4.2 Impact on Miniaturization

The use of Kapton tape in the HoloLens 3 led to a significant reduction in the overall size and weight of the device. The 40% reduction in waveguide thickness, enabled by the tape's ultra - thin profile, allowed for a more compact design. This not only made the HoloLens 3 more comfortable to wear but also improved its portability. Additionally, the high - temperature resistance of the tape ensured that the device could withstand the rigorous manufacturing processes, contributing to its overall reliability.

5. Comparison with Other Tapes

5.1 Brown Circuit Board High Temperature Tape

Brown circuit board high temperature tape is thicker than Kapton tape, which limits its ability to contribute to miniaturization. Its lower optical clarity also makes it less suitable for applications in AR glasses waveguides. In terms of heat resistance, it cannot match the 400°C solder reflow resistance of Kapton tape, which may lead to issues during manufacturing.

5.2 Adhesive PET Material High Temperature Tape

Adhesive PET material high temperature tape has a relatively low heat resistance compared to Kapton tape. This makes it unsuitable for the high - temperature soldering processes involved in AR glass manufacturing. While it may be thinner than Brown circuit board high temperature tape, it still does not offer the same level of performance in terms of optical clarity and high - temperature stability as Kapton tape.

6. Future Implications and Potential Developments

6.1 Further Miniaturization

As the demand for even more compact AR glasses continues to grow, the innovative features of Gold Finger Electronics Polyimide Tape Kapton will likely play an even more significant role. Future developments may focus on reducing the tape's thickness even further while maintaining or improving its other properties, such as heat resistance and optical clarity.

6.2 Integration with Emerging Technologies

AR technology is constantly evolving, with new features such as higher - resolution displays and more advanced sensor integration. Kapton tape's properties make it well - positioned to be integrated with these emerging technologies. For example, its high - temperature resistance and electrical insulation properties could be beneficial in the development of more powerful and energy - efficient AR glasses.

7. Conclusion

Gold Finger Electronics Polyimide Tape Kapton's innovative features, including its ultra - thin profile, high - temperature resistance, and excellent optical clarity, have been instrumental in enabling miniaturization in AR glasses, as demonstrated by the Microsoft HoloLens 3 case study. Compared to Brown circuit board high temperature tape and Adhesive PET material high temperature tape, Kapton tape offers superior performance in key areas that are crucial for AR device development. As the AR industry continues to grow, the role of Kapton tape in driving miniaturization and improving device performance is likely to become even more important. To learn more about the applications of Gold Finger Electronics Polyimide Tape Kapton in AR glasses and other high - tech devices, you can download our in - depth technical report available at [download link]. This report provides detailed analysis and additional case studies for a comprehensive understanding.

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT