How to Select Between Transparent PI Film and Metallized Film for Gold Finger Electronics Applications?|https://www.lvmeikapton.com/

1. Introduction

1.1 Background of Gold Finger Electronics

In the intricate world of electronics, gold finger connections are pivotal. These slender strips, featuring electroplated copper contacts with a gold coating, facilitate smooth data transmission and electrical connectivity. They are indispensable in a vast array of devices, from smartphones and laptops to complex medical equipment and aerospace systems. Gold fingers ensure stable connections, reducing resistance and corrosion, thus enhancing device reliability and longevity. As technology advances and devices become more sophisticated, the demand for gold finger electronics is soaring. Industries like telecommunications, which rely on seamless network connections, and consumer electronics, where high performance is expected, are driving this growth. The aerospace sector, with its stringent requirements for precision and durability, also heavily depends on gold finger technology. The increasing integration of electronics in various fields underscores the crucial role and significance of gold finger electronics.

1.2 Importance of PI Films in Gold Finger Applications

PI films play a vital role in gold finger applications, primarily serving as insulation and protection. Their exceptional thermal stability allows them to withstand extreme temperatures, ensuring functionality in diverse environments. Their chemical resistance shields gold fingers from corrosion and degradation caused by harsh chemicals. Moreover, PI films boast high mechanical strength, preventing physical damage and maintaining structural integrity. These films have a low dielectric constant, reducing signal loss and ensuring efficient data transmission. Their transparency, in the case of transparent PI films, enables visual inspection and ease of integration. Overall, PI films' unique properties make them indispensable in protecting gold fingers and enhancing their performance, reliability, and lifespan in various electronic applications.

2. Material Composition and Core Properties

2.1 Transparent PI Film

2.1.1 Material Composition

Transparent PI film, exemplified by Kapton® HN, is a pure polyimide polymer. Its chemical structure is based on aromatic rings connected by imide groups, forming a highly stable and robust molecular chain. The synthesis of Kapton® HN involves a two-step process. First, monomers such as dianhydrides and diamines react to form a polyamic acid solution. This solution is then applied to a substrate and heated to drive off water, leading to the formation of the polyimide film. The raw materials used are carefully selected to ensure the film's superior properties, including high purity dianhydrides and diamines. This precise synthesis process results in a transparent PI film with exceptional performance characteristics, making it highly suitable for gold finger electronics applications.

2.1.2 Core Properties

Transparent PI film boasts remarkable thermal stability, enabling it to function seamlessly in extreme temperature conditions. Its working temperature range spans from a frigid -269°C to a scorching 400°C, making it ideal for applications in environments with wide temperature fluctuations. The film demonstrates excellent chemical resistance, withstanding common chemicals like acids, bases, and solvents. It remains stable and undamaged when exposed to these harsh substances, protecting gold fingers from corrosion. Moreover, transparent PI film features high透光性, with visible light transmittance typically exceeding 80%. This transparency allows for visual inspection of underlying components and facilitates easier integration into complex electronic systems, enhancing its实用性 in gold finger applications.

2.2 Metallized PI Film

2.2.1 Material Composition

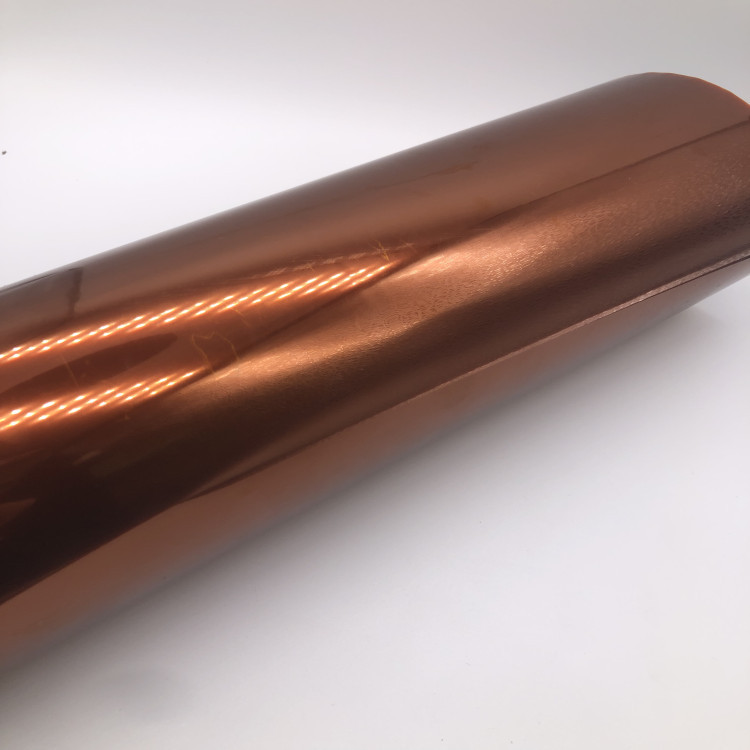

Metallized PI film is crafted by adding a metal layer to a PI film substrate via techniques such as vacuum metallization. Commonly used metals include aluminum and copper. The thickness of the metal layer, typically ranging from a few nanometers to several microns, plays a crucial role in determining the film's properties. Thinner layers may offer flexibility, while thicker ones provide better conductivity and shielding. The preparation process, including the choice of deposition method and parameters, significantly impacts the film's performance, ensuring a strong bond between the metal and PI layers and consistent quality.

2.2.2 Core Properties

Metallized PI film exhibits excellent导电性能. The addition of metal layers like aluminum (with a conductivity of around 3.77×10^7西门子每米) and copper (5.96×10^7西门子每米) significantly enhances the导电 capabilities of gold fingers. This improved conductivity reduces resistance in electrical circuits, facilitating faster and more efficient data transmission. In terms of electromagnetic shielding, metallized PI film performs exceptionally well. The metal layer acts as a barrier, reflecting and absorbing electromagnetic waves, thereby shielding the underlying gold fingers from external interference. The屏蔽效能, measured in decibels (dB), indicates the film's ability to reduce the strength of electromagnetic fields. With high shielding effectiveness, metallized PI film ensures stable and reliable operation of gold finger electronics in environments with strong electromagnetic interference.

3. Performance Trade - offs

3.1 Thermal Stability

In high-temperature environments, transparent PI film and metallized PI film exhibit distinct performance differences. Transparent PI film, owing to its pure polyimide composition, maintains remarkable stability. Studies show that at 300°C, Kapton® HN retains over 80% of its initial tensile strength, highlighting its resilience in extreme heat. In contrast, the addition of a metal layer to metallized PI film can alter its thermal stability. The differing thermal expansion coefficients of the metal and PI layers may lead to internal stresses upon heating, potentially causing delamination or other structural issues. For instance, when aluminum is metallized onto PI, the mismatch in thermal expansion can result in stress concentrations. Data from tests conducted in high-temperature environments demonstrate that transparent PI film experiences less deformation and retains better mechanical integrity, making it the preferred choice for applications where prolonged exposure to high temperatures is expected.

3.2 Optical Properties

Transparent PI film shines in applications that require light transmission. Its high visible light transmittance, typically above 80%, enables it to be used in devices like optical sensors, touchscreens, and LED lighting systems, where light needs to pass through the material. The transparency allows for accurate sensing and visual display, enhancing the functionality and performance of these electronics. Conversely, metallized PI film, due to its metal layer, blocks light. This makes it unsuitable for optical applications but highly applicable in scenarios where light transmission is not needed. In applications like electromagnetic shielding for cables or in areas with strong light interference, the light-blocking property of metallized PI film can be advantageous, preventing unwanted light effects and ensuring stable operation of the electronics.

3.3 Electrical and Electromagnetic Performance

In terms of electrical and electromagnetic performance, metallized PI film stands out. Its metal layer significantly enhances conductivity, reducing electrical resistance and facilitating faster data transmission in circuits. This makes it ideal for applications that demand high electrical efficiency, such as in high-frequency communication devices. Additionally, metallized PI film offers excellent electromagnetic shielding, protecting gold fingers from external interference and ensuring reliable signal transmission. Transparent PI film, on the other hand, excels in electrical insulation. Its high dielectric strength, exceeding 7 kV/mm, effectively prevents electrical breakdown and ensures safe operation in electronic systems where insulation is crucial.

4. Application - Specific Demands

4.1 High - Temperature Environments

In high-temperature electronic devices like automotive engine control systems and aerospace electronics, transparent PI film emerges as the more suitable choice due to its exceptional thermal stability. In automotive engine control systems, which operate in environments with temperatures often exceeding 150°C, transparent PI film can maintain its mechanical integrity and electrical insulation properties. Kapton® HN, for instance, retains over 80% of its initial tensile strength at 300°C, ensuring the reliability of gold finger connections. In aerospace electronics, where equipment is exposed to extreme temperatures during launch and operation, transparent PI film's wide working temperature range of -269°C to 400°C makes it indispensable. It is commonly used in aerospace sensors and control units, preventing performance degradation due to temperature fluctuations, thus ensuring the safety and functionality of aerospace systems.

4.2 Electromagnetic Interference (EMI) Protection

In scenarios where electromagnetic interference (EMI) is a significant concern, such as in communication devices and computers, metallized PI film provides crucial protection for gold finger electronics. Its metal layer effectively reflects and absorbs electromagnetic waves, shielding the underlying gold fingers from external interference. According to the IEC 61000-4-3 standard for testing electromagnetic shielding effectiveness, metallized PI films can achieve shielding effectiveness of up to 60 dB at frequencies ranging from 30 MHz to 1 GHz. This means that the strength of electromagnetic fields reaching the gold fingers is reduced by a factor of 10^6, ensuring stable and reliable operation of electronic devices. In communication base stations, where strong EMI is common, metallized PI film protects gold finger connections in circuit boards, preventing data corruption and signal degradation, thus maintaining the quality of communication services.

4.3 Optical Applications

In optical applications like光电设备 and display panels, transparent PI film plays a pivotal role. Its high visible light transmittance ensures excellent display effects and quality of optical signal transmission. In touchscreens, transparent PI film allows light to pass through, enabling accurate touch sensing and vibrant visual display. In LED lighting systems, it ensures efficient transmission of light, enhancing the luminous efficacy and color rendering of the lights. Transparent PI film's transparency and durability make it ideal for use in these applications, where both performance and reliability are essential.

5. Cost Considerations

5.1 Production Costs

In the production of transparent PI film and metallized PI film, significant cost differences exist. Transparent PI film, like Kapton® HN, is made from pure polyimide polymer. Its raw materials, such as high-purity dianhydrides and diamines, contribute to the cost. The synthesis process, involving the formation of polyamic acid and subsequent heating, is relatively straightforward. Metallized PI film, on the other hand, requires additional steps for the metal layer deposition. Techniques like vacuum metallization using metals like aluminum and copper increase material costs. The complexity of the preparation process, ensuring a strong bond between metal and PI layers, also adds to costs. Overall, metallized PI film production costs are higher due to the additional metal layer and more intricate manufacturing process.

5.2 Processing Costs

During processing, such as cutting and molding, costs can vary for transparent PI film and metallized PI film. Transparent PI film, with its inherent flexibility and stability, is easier to handle and process. It can be readily cut and shaped using standard techniques without much complexity. Metallized PI film, however, poses challenges. The metal layer can make it more rigid and prone to damage during cutting, requiring specialized tools and techniques. This increases processing time and the risk of material waste, driving up costs. Moreover, molding metallized PI film may demand higher temperatures or specific conditions to avoid damaging the metal layer, adding to the overall processing expense.

5.3 Overall Cost Impact on Decision-making

The combined production and processing costs play a crucial role in the decision-making process. Metallized PI film generally costs more due to its additional materials and complex production and processing requirements. In applications with limited budgets and no need for electromagnetic shielding or enhanced conductivity, transparent PI film is a cost-effective choice. For instance, in basic LED lighting systems where light transmission is key, transparent PI film saves costs. However, in high-end communication devices requiring EMI protection, despite the higher costs, metallized PI film is essential. Cost analysis must consider the application's specific needs, balancing performance requirements with budget constraints to make an informed decision.

6. Technological Trends and Future Directions

6.1 Advancements in Gold Finger Electronics Technology

Gold finger electronics technology is advancing rapidly, with trends toward higher density, smaller dimensions, and more demanding performance requirements. Devices are becoming increasingly miniaturized, necessitating gold fingers with finer pitch and greater precision. Higher data transmission speeds require enhanced electrical conductivity and reduced signal loss. This pushes the boundaries for PI films, demanding materials that can withstand higher temperatures, offer better electrical and electromagnetic performance, and maintain stability in more compact and complex structures.

6.2 New Requirements for PI Films

To keep pace with the evolving gold finger electronics landscape, both transparent and metallized PI films must undergo significant improvements. Transparent PI film needs to achieve even higher thermal stability to operate reliably in extreme environments, such as in next-generation aerospace applications where temperatures may reach new extremes. It should also enhance its optical properties, with greater light transmittance and reduced haze for clearer visual displays in advanced touchscreens and optical sensors. Metallized PI film must boost its electromagnetic shielding effectiveness, reaching higher decibel levels to protect against increasingly powerful electromagnetic interference in high-tech communication systems. Additionally, it should improve conductivity to facilitate faster data transmission in high-frequency applications.

6.3 Future Development Directions

The future of transparent and metallized PI films lies in innovative material research and advanced preparation techniques. New materials may emerge, combining the strengths of polyimide with other high-performance polymers or incorporating nanomaterials to enhance properties. Preparation processes could evolve, utilizing precision deposition methods and advanced manufacturing technologies to fine-tune film characteristics. These advancements could open new application possibilities in emerging fields like flexible electronics, wearable technology, and the Internet of Things, driving market growth and transforming the electronics industry.

7. Conclusion

7.1 Summary of Key Points

Transparent PI film and metallized PI film differ significantly. Transparent PI film, with its pure polyimide composition, excels in thermal stability and optical transparency, making it ideal for high-temperature and optical applications. Metallized PI film, featuring a metal layer, offers enhanced electrical conductivity and electromagnetic shielding, well-suited for EMI protection and high-frequency communication. Cost-wise, metallized PI film is generally more expensive due to its complex production and processing. These characteristics define their unique roles in gold finger electronics.

7.2 Guidelines for Selection

When selecting between transparent PI film and metallized PI film for gold finger electronics, consider the application environment, performance requirements, and budget constraints. In high-temperature or optical applications, transparent PI film is preferred. For EMI protection and high electrical efficiency, choose metallized PI film. Always weigh the trade-offs and prioritize the most critical factors to make an informed decision.

7.3 Outlook for Future Research and Development

The future of PI films in gold finger electronics holds great potential. Research will likely focus on developing materials with higher thermal stability, better electrical and electromagnetic performance, and improved optical properties. Innovations may include integrating nanotech or exploring new polymer blends. Advancements will cater to emerging fields like flexible electronics, pushing the boundaries of gold finger technology and expanding its applications.

References

[1] Lvmei Kapton. (n.d.). How to Select Between Transparent PI Film and Metallized Film for Gold Finger Electronics Applications? Retrieved from https://www.lvmeikapton.com/

[2] IEC. (2010). IEC 61000-4-3: Electromagnetic compatibility (EMC) - Part 4-3: Testing and measurement techniques - Radiated, radio-frequency, electromagnetic field immunity test. International Electrotechnical Commission.

[3] DuPont. (2023). Kapton® Polyimide Film. Retrieved from https://www.dupont.com/content/dam/dupont/amer/zh_Hans/kapton/pdfs/kapton-hn.pdf

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |