How Does Polyimide Tape's Tensile Strength Impact Gold Finger Reliability in Electronics Manufacturing? |https://www.lvmeikapton.com/

1. Introduction

1.1 Background of Electronics Manufacturing

The electronics manufacturing industry has undergone a remarkable transformation in recent decades, driven by technological advancements and growing consumer demand. As devices become increasingly smaller, more powerful, and interconnected, the role of connectors is paramount. Gold fingers, tiny strips of gold-plated copper or nickel, serve as vital bridges between printed circuit boards (PCBs) and external devices, facilitating data and power transmission. To protect these delicate components during production and operation, polyimide tape, particularly Kapton tape, is widely employed. Kapton tape, known for its exceptional thermal stability and chemical resistance, provides a reliable barrier against physical damage, moisture, and other environmental factors. Its use is indispensable in ensuring the integrity and functionality of gold fingers, ultimately contributing to the overall reliability of electronic devices.

1.2 Significance of the Research

Investigating the relationship between polyimide tape's tensile strength and gold finger reliability is of utmost importance. In the competitive landscape of electronics manufacturing, where precision and quality are paramount, even minor defects can lead to costly production delays and product recalls. Understanding how tensile strength affects gold finger performance can help manufacturers optimize production processes, reducing material waste and improving yields. Moreover, it ensures the long-term durability and reliability of electronic devices, enhancing user experience and product longevity. From a technological standpoint, this research contributes to the advancement of materials science and electronics engineering, paving the way for innovative solutions in high-performance applications such as aerospace, medical devices, and consumer electronics. By exploring this critical aspect, the industry can continue to push the boundaries of technology, delivering more reliable and sophisticated products to meet the evolving needs of society.

2. Properties of Polyimide Tape

2.1 General Characteristics of Polyimide Tape

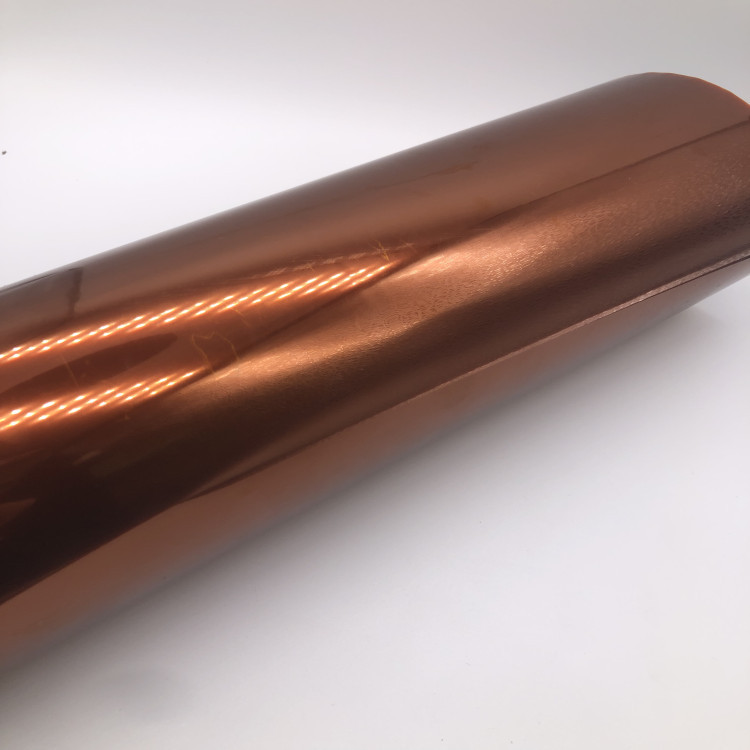

Polyimide tape boasts an array of remarkable properties that make it indispensable in electronics manufacturing. Its thermal stability is unparalleled, enabling it to withstand temperatures ranging from -269°C to +400°C without significant degradation. This ensures that the tape remains functional and protective even in extreme thermal environments, making it ideal for applications involving high-temperature processes like soldering. Mechanically, polyimide tape is exceptionally tough, resisting tears, punctures, and abrasions. It maintains its integrity under pressure, protecting gold fingers from physical damage during handling and assembly. Chemically, it's highly resistant to acids, alkalis, solvents, and oils, shielding sensitive components from corrosion and contamination. Kapton tape, in particular, stands out with its combination of these properties, offering superior protection and reliability in a wide range of applications.

2.2 Definition and Importance of Tensile Strength

Tensile strength, a crucial property of polyimide tape, refers to the maximum stress the material can endure before breaking under tension. It's a key indicator of the tape's durability and resilience. In electronics manufacturing, where gold fingers are subjected to various forces during lamination, soldering, and post-processing, tensile strength plays a pivotal role. A tape with high tensile strength can better withstand stretching and pulling forces, preventing tears and ensuring a secure bond. It ensures that the tape remains intact, maintaining its protective function throughout the manufacturing process. Conversely, low tensile strength can lead to tape failure, compromising the integrity of gold fingers and potentially causing production defects. Therefore, understanding and optimizing tensile strength is essential for ensuring the reliability and performance of electronic devices that rely on gold fingers.

3. Impact of Tensile Strength on Gold Finger Reliability

3.1 During Lamination

In the lamination process, the tensile strength of polyimide tape plays a critical role in maintaining the integrity of gold fingers. When tape with inadequate tensile strength is subjected to the forces involved in lamination, it can easily deform. This deformation causes the tape to not lay flat or adhere evenly to the gold finger surface, leading to air pockets and weak adhesive bonds. These issues can compromise the protection provided by the tape, making the gold fingers more susceptible to physical damage and contamination. Moreover, during lamination, if the tape stretches excessively due to low tensile strength, it can apply uneven pressure to the gold fingers. This pressure can cause microscopic scratches or distortions on the gold surface, which can impact electrical conductivity and overall reliability. Inadequate tensile strength can also lead to tape delamination, where the tape peels away from the gold fingers, completely negating its protective purpose and potentially causing production defects.

3.2 During Soldering

Soldering is a crucial stage where the tensile strength of polyimide tape becomes especially important for gold finger reliability. During soldering, high temperatures are applied, and the tape is subjected to thermal expansion and contraction forces. If the tape lacks sufficient tensile strength, it may lift or curl away from the gold fingers, exposing sensitive areas to molten solder. This can lead to solder bridging, where solder flows between adjacent gold fingers, causing electrical shorts and rendering the component unusable. Tape lifting can also lead to uneven solder joints, creating weak points that are prone to failure over time. Moreover, low tensile strength tape may not withstand the mechanical stresses generated during soldering, leading to tears or breaks in the tape. These defects not only compromise the immediate functionality of the gold fingers but also affect their long-term reliability, as they are more likely to experience corrosion and degradation due to inadequate protection.

3.3 Post-processing

Post-processing stages present unique challenges for gold fingers, largely dependent on the tensile strength of polyimide tape. One significant issue is tape residue. If the tape does not have the right balance of tensile strength and adhesive properties, removing it after processing can leave behind a sticky residue on the gold fingers. This residue attracts dust and debris, leading to surface contamination that can affect electrical performance. Moreover, during post-processing, gold fingers may be subjected to cleaning processes or mechanical handling. Inadequate tensile strength in the tape can lead to premature degradation, as the tape may not provide sufficient protection against the forces involved. Over time, this can cause wear and tear on the gold fingers, leading to reduced conductivity and eventual failure. The long-term reliability of electronic devices is thus directly impacted by the tensile strength of the polyimide tape used to protect the gold fingers, highlighting the importance of this property in ensuring product longevity and performance.

4. Challenges and Solutions

4.1 Environmental Factors

Environmental conditions, particularly temperature and humidity, can significantly impact the tensile strength of polyimide tape, thereby affecting gold finger reliability. At high temperatures, polyimide tape may experience thermal expansion, which can alter its tensile properties. If the tape is not designed to withstand the specific temperature range, it may become less durable, leading to potential tears or delamination during manufacturing or operation. Humidity, on the other hand, can cause the tape to absorb moisture, weakening its adhesive properties and reducing its overall tensile strength. This can result in issues like tape lifting or adhesive failure, compromising the protection of gold fingers. To mitigate these effects, manufacturers should store polyimide tape in controlled environments with stable temperature and humidity levels. During production, temperature and humidity should be closely monitored and maintained within acceptable ranges. Using polyimide tapes with enhanced resistance to temperature and humidity, such as those with specialized coatings or additives, can also provide additional protection and ensure the long-term reliability of gold fingers.

4.2 Optimization of Tape Selection

Selecting polyimide tapes with appropriate tensile strength for specific gold finger applications is crucial for ensuring reliability. The manufacturing processes employed play a significant role in tape selection. For example, if the process involves high temperatures or mechanical stress, tapes with higher tensile strength and better heat resistance are necessary. Environmental conditions where the final device will be used also influence tape choice. Harsh environments, such as those with high humidity or extreme temperatures, require tapes that are specifically designed to withstand such conditions. Device requirements, including the expected lifespan and performance demands, should also be considered. For applications where durability and longevity are paramount, tapes with superior tensile strength and long-term stability are preferred. Conducting thorough testing and analysis of different tape options under simulated conditions can help identify the most suitable tape for a given application. Collaborating with tape manufacturers to develop custom solutions tailored to specific requirements can also provide enhanced performance and reliability.

4.3 Improvement of Manufacturing Processes

To enhance the compatibility between polyimide tape and gold fingers, optimizing lamination and soldering parameters is essential. Lamination should be performed at controlled temperatures and pressures to prevent excessive stretching or deformation of the tape. Adjusting the speed and pressure of the lamination process can ensure a smooth and secure bond between the tape and gold fingers. In soldering, precise temperature control is crucial to prevent tape lifting or degradation. Using advanced soldering techniques, such as selective soldering or laser soldering, can reduce thermal stress on the tape and gold fingers. Improving surface preparation is also important. Ensuring that gold finger surfaces are clean and free of contaminants can enhance adhesive bonding and prevent tape delamination. Utilizing advanced application methods, like automated tape application systems, can improve consistency and accuracy, reducing the risk of human error and enhancing overall reliability.

5. Future Directions

5.1 Emerging Technologies

In the rapidly evolving landscape of electronics manufacturing, emerging technologies are continually reshaping the relationship between polyimide tape's tensile strength and gold finger reliability. Miniaturization trends demand even thinner and more precise gold fingers, necessitating polyimide tapes with exceptional tensile strength to maintain integrity during fabrication and operation. High-density interconnects increase the complexity of connections, making tape durability critical to prevent electrical issues. Advanced materials like graphene and carbon nanotubes may offer enhanced properties, potentially requiring tapes with tailored tensile strengths to complement their unique characteristics. As these technologies advance, the role of tensile strength in ensuring gold finger reliability becomes increasingly complex and essential.

5.2 Research Opportunities

There are several promising research areas to further explore the impact of tensile strength on gold finger reliability. Developing new tape materials that offer improved tensile strength while retaining other desirable properties is a key focus. Optimizing multi-layer tape structures to balance strength, flexibility, and adhesive properties could enhance protection for gold fingers. Improving testing and evaluation methods to more accurately assess tape performance under various conditions is also crucial. These research efforts will contribute to advancing the reliability of electronic devices and meeting the demands of emerging technologies.

6. Conclusion

6.1 Summary of Findings

In the intricate world of electronics manufacturing, polyimide tape's tensile strength has a profound impact on gold finger reliability. During lamination, inadequate tensile strength can lead to tape deformation, air pockets, and weak adhesive bonds, compromising gold finger protection. In soldering, low tensile strength causes tape lifting and curling, increasing the risk of solder bridging and electrical shorts. Post-processing issues like tape residue and premature degradation are also exacerbated by insufficient tensile strength. Environmental factors, tape selection, and manufacturing processes pose challenges, but careful consideration and optimization can mitigate these issues. The significance of tensile strength cannot be overstated; it is pivotal in ensuring the durability, conductivity, and long-term performance of gold fingers, ultimately impacting the reliability of electronic devices.

6.2 Implications and Outlook

This research holds significant implications for the electronics manufacturing industry. As devices continue to evolve, with increasing miniaturization and complexity, the importance of polyimide tape's tensile strength will only grow. Manufacturers must prioritize tape selection and process optimization to meet the demands of emerging technologies. The industry is likely to witness the development of innovative polyimide tapes with enhanced tensile strength and specialized properties to accommodate advanced materials and fabrication techniques. Further research in this area will unlock new possibilities for improving gold finger reliability, reducing production costs, and enhancing product performance. By continually advancing our understanding of the relationship between tensile strength and gold finger integrity, the electronics manufacturing industry can stay ahead of the curve, delivering more reliable and sophisticated products to meet the ever-changing needs of consumers and industries alike.

References

1.

Lvmeikapton. (n.d.). How Does Polyimide Tape's Tensile Strength Impact Gold Finger Reliability in Electronics Manufacturing? Retrieved from https://www.lvmeikapton.com/

2.

Polyimide Tape. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Polyimide_tape

3.

Kapton Tape. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Kapton_tape

4.

Gold Finger. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Gold_finger

5.

Printed Circuit Board. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Printed_circuit_board

6.

Electronics Manufacturing. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Electronics_manufacturing

7.

Tensile Strength. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Tensile_strength

8.

Soldering. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Soldering

9.

Miniaturization. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Miniaturization

10.

High-Density Interconnect. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/High-Density_Interconnect

11.

Graphene. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Graphene

12.

Carbon Nanotubes. (n.d.). In Wikipedia. Retrieved from https://en.wikipedia.org/wiki/Carbon_nanotube

Material | Temperature Resistance (°C) | Flexibility | Chemical Resistance | Electrical Insulation |

PI Tape | Up to 300°C | High | Excellent | Excellent |

Ceramic Tape | Up to 1000°C | Low | Good | Good |

Glass Cloth Tape | Up to 500°C | Medium | Good | Good |

Aluminum Foil Tape | Up to 200°C | Low | Fair | Poor |