Case 1: Circuit Board Reflow Protection

An electronics factory used polyimide-based high-temperature tape to mask sensitive components on its SMT reflow circuit boards. The tape, with a temperature resistance of 260℃, maintained stable adhesion during the reflow process, preventing solder contamination of components. It also possessed excellent insulation properties, avoiding the risk of short circuits between components. After its use, the reflow yield of the circuit boards improved by 20%, while reducing rework costs due to contamination.

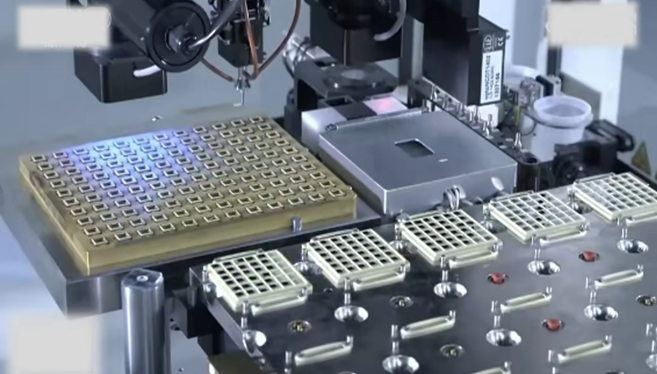

Case Study 2: Semiconductor Wafer Spray Masking A semiconductor company used PET-based high-temperature tape to mask the edges of its 12-inch wafers during the spray process. The tape, with a temperature resistance of 200℃ and adjustable adhesion, could adapt to the curved surface of the wafer. Through precise cutting, the tape achieved accurate masking of the spray area, preventing spray material from entering non-target areas, improving wafer yield to 99%, and reducing waste costs due to contamination.