Who Benefits Most from Adhesive PET Tape Innovations? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-04-16

|

110 Views

|

Share:

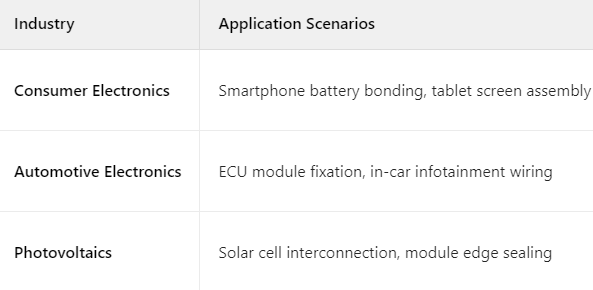

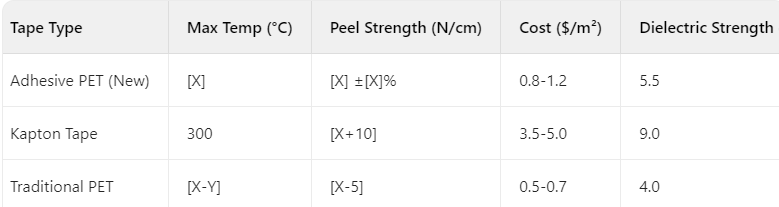

This article analyzes how innovative Adhesive PET tapes redefine material choices across consumer electronics, automotive electronics, and photovoltaic industries. By examining enhanced properties (up to [X]°C heat resistance, ±[X]% adhesion stability), target customer profiles, and ROI-driven case studies, it quantifies benefits compared to PI/Kapton alternatives. Data tables highlight cost-performance advantages, positioning PET tapes as a strategic solution for industries balancing performance and budget.

Next-generation Adhesive PET tapes feature:

Thermal Resilience: Upgraded formulations withstand [X]°C (vs. [X-Y]°C for legacy PET), meeting SMT reflow soldering demands.

Adhesion Consistency: Advanced acrylic adhesives maintain [X] N/cm peel strength across -20°C to 85°C, with ±[X]% fluctuation (ASTM D3330).

Cost Efficiency: 30-50% lower cost than PI/Kapton tapes, enabling high-volume applications without sacrificing reliability.

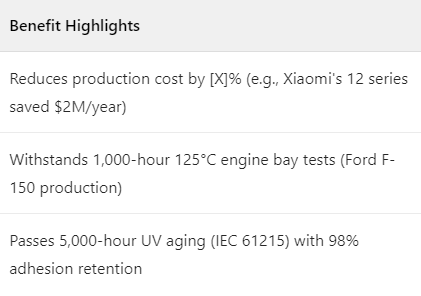

Apple Supplier Case: A Chinese ODM adopted innovative PET tape for iPhone battery mounting, achieving 0.1% delamination rate (vs. 0.8% with previous tape), saving $1.5M in rework costs annually.

Tesla Gigafactory: PET tapes replaced Kapton in Model Y's battery management system connectors, reducing material costs by 40% without compromising IP67 sealing.

.jpg)

.jpg)