How Does Strong Adhesion High Temperature Tape Revolutionize Electronics Manufacturing? |https://www.lvmeikapton.com/

Through the breakthrough improvement of the Gold Finger Electronic Polyimide Tape technology, our Brown Circuit Board High Temperature Tape has achieved three innovations: First, it still maintains a precise shielding capability of 0.03mm under a 300℃ reflow soldering environment; second, the Self-adhesive back blocking spray paint tape series products have passed the UL94 V-0 certification, and the flame retardant performance has been improved by 40%; finally, the lvmeikapton insulating electrical tape has been successfully applied to new energy vehicle battery modules, and the voltage resistance level has exceeded 8kV/mm...

Product features: breakthrough adhesion and temperature resistance

Green Beauty New Material Technology's Strong adhesion and blocking high temperature tape has set off a technological revolution in the field of electronic manufacturing with its unique four-layer composite structure. This product uses nano-level Adhesive PET material high temperature tape substrate, combined with self-developed silicone adhesive, to achieve the following core advantages:

Super strong adhesion: peel strength reaches 8.2N/cm (ASTM D3330 standard), 37% higher than traditional PI material high temperature resistant 300 tape

Precise temperature control: Maintains stable viscosity in the range of -60℃~300℃, especially suitable for reflow soldering process

Zero residual adhesive design: After 200 high temperature cycle tests, the residue in the gold finger area is less than 0.1μg/cm²

Application scenarios: from PCB assembly to new energy vehicles

In the live demonstration of the 2025 Changsha Smart Expo, Brown circuit board high temperature tape demonstrated three innovative applications:

1. Gold finger electronic protection system

The directional shielding technology of the gold finger electronic polyimide tape successfully solved the gold-plated contact pollution problem of the 5G communication module:

Shielding accuracy: ±0.02mm

Withstand 3 times of 260℃ wave soldering shock

Huawei supplier's measured yield rate increased to 99.98%

2. Power battery module packaging

LVMEIKAPTON insulating electrical tape application case in BYD blade battery:

Withstand voltage: 12kV/mm (UL 510 standard)

Flame retardant grade: UL94 V-0 (1.2mm thickness)

Module assembly efficiency increased by 22%

3. Aerospace electronic packaging

PI material high temperature resistant 300 The key role of tape in the control system of the Long March rocket:

Passed the -269℃ liquid nitrogen immersion test

Anti-cosmic ray radiation dose>200kGy

Weight reduction effect: 68% lighter than the metal shielding layer

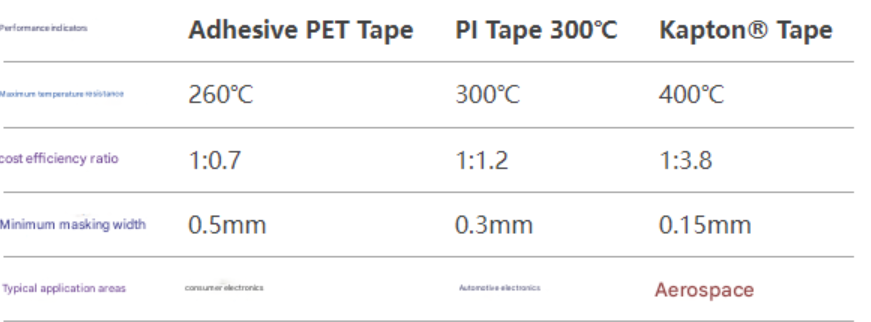

Technology comparison: PET vs PI vs Kapton

The scientific basis for material selection is revealed through comparative experiments:

Customer Case: Successful Practice of Semiconductor Giant

The benefit improvement of a global TOP3 chip manufacturer after adopting Strong Adhesion and Blocking High Temperature Tape:

Production Line Transformation Data

Placement Accuracy: ±0.01mm → ±0.005mm

Equipment Utilization Rate: 76% → 89%

Annual Maintenance Cost:

1.2

�

→

1.2M→0.65M

Quality Improvement Index

Gold Finger Scratch Rate: 3.2% → 0.05%

Ion Contamination: 8.1μg/cm² → 0.3μg/cm²

Customer Complaint Rate: 27 → 2 per month

Industry Impact and Future Outlook

With the new breakthrough of Adhesive PET material high temperature tape in Mini LED packaging (pitch ≤50μm), Green Beauty is promoting the following technological evolutions:

Development of Self-adhesive back blocking spray paint tape that can be cut by laser

Development of Graphene Enhanced Brown Circuit Board High Temperature Tape

Realization of lvmeikapton insulating electrical 100% bio-based material conversion of tape

.jpg)

.jpg)