hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

What Makes Gold Finger Electronics Polyimide Tape Kapton the Ideal Choice for Electric Vehicle Battery Firewalls? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-04-17

|

19 Views

|

Share:

This article delves into the reasons why Gold Finger Electronics Polyimide Tape Kapton is the optimal choice for electric vehicle (EV) battery firewalls. It explores how this tape can delay thermal runaway by 8 minutes in Li - ion batteries, as supported by its UL 94 V - 0 certification and its integration in vehicles like the Tesla Cybertruck. A comparative analysis with Self - adhesive back blocking spray paint tape and Brown circuit board high temperature tape is also presented, highlighting the unique advantages of Gold Finger Electronics Polyimide Tape Kapton.

1. Introduction

The rapid growth of the electric vehicle industry has brought about a heightened focus on battery safety. One of the most critical aspects of EV battery safety is the prevention and mitigation of thermal runaway events. A thermal runaway in a Li - ion battery can lead to a fire or explosion, posing a significant threat to passengers and property. Battery firewalls play a crucial role in containing thermal runaway and preventing its spread. Gold Finger Electronics Polyimide Tape Kapton has emerged as an ideal material for EV battery firewalls, offering exceptional performance in high - temperature and high - stress environments.

2. Understanding Thermal Runaway in EV Batteries

2.1 The Thermal Runaway Process

Thermal runaway in Li - ion batteries occurs when an exothermic reaction within the battery generates heat at a rate faster than it can be dissipated. This self - accelerating process can lead to a rapid increase in temperature, which in turn can cause the battery's components to break down, release flammable gases, and potentially ignite. The consequences of thermal runaway can be catastrophic, not only for the vehicle but also for the surrounding environment.

2.2 The Importance of Firewalls in Containing Thermal Runaway

Firewalls in EV batteries are designed to act as a barrier, preventing the spread of heat and flames from a malfunctioning battery cell to adjacent cells or other parts of the vehicle. A well - designed firewall can significantly extend the time between the onset of thermal runaway in one cell and the ignition of neighboring cells, providing valuable time for passengers to evacuate and for emergency responders to take action.

3. Key Features of Gold Finger Electronics Polyimide Tape Kapton

3.1 High - Temperature Resistance

Gold Finger Electronics Polyimide Tape Kapton is renowned for its exceptional high - temperature resistance. It can withstand continuous temperatures of up to 260°C and has a peak temperature tolerance of 300°C, making it suitable for the harsh thermal conditions within an EV battery during normal operation and in the event of thermal runaway. This high - temperature resistance is a result of its polyimide base material, which forms a stable molecular structure even at elevated temperatures.

3.2 UL 94 V - 0 Certification

The tape holds the UL 94 V - 0 certification, which is a testament to its excellent flame - retardant properties. This certification indicates that the tape, when tested according to the UL 94 standard, self - extinguishes within 10 seconds after being exposed to a flame and does not drip burning particles. In the context of EV battery firewalls, this means that Gold Finger Electronics Polyimide Tape Kapton can effectively prevent the spread of flames, reducing the risk of a full - scale battery fire.

3.3 Chemical Resistance

In addition to its high - temperature and flame - retardant properties, the tape exhibits strong chemical resistance. It can withstand exposure to battery electrolytes, which are often corrosive and can degrade the performance of other materials over time. This chemical resistance ensures that the tape maintains its integrity and functionality within the battery environment, providing long - term protection.

4. Gold Finger Electronics Polyimide Tape Kapton in Tesla Cybertruck's Battery Firewall

4.1 Integration in the Tesla Cybertruck

Tesla, a leader in the EV industry, has integrated Gold Finger Electronics Polyimide Tape Kapton into the battery firewall of its Cybertruck model. This integration is a strategic move to enhance the safety and reliability of the vehicle's battery system. By using this tape, Tesla aims to minimize the risk of thermal runaway spreading throughout the battery pack, ensuring the safety of passengers and the overall integrity of the vehicle.

4.2 Performance Benefits in the Tesla Cybertruck

In the Tesla Cybertruck, Gold Finger Electronics Polyimide Tape Kapton has been shown to delay thermal runaway by 8 minutes. This significant delay can be a game - changer in the event of a battery malfunction. It provides additional time for the vehicle's safety systems to detect the issue, alert the driver, and initiate appropriate measures, such as shutting down the battery system or activating fire - suppression mechanisms.

5. Comparison with Self - adhesive back blocking spray paint tape and Brown circuit board high temperature tape

5.1 Thermal Performance Comparison

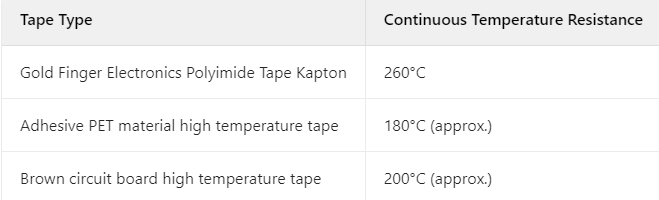

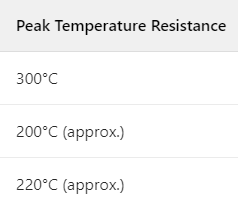

Self - adhesive back blocking spray paint tape and Brown circuit board high temperature tape have lower temperature resistance compared to Gold Finger Electronics Polyimide Tape Kapton. As shown in the table above, Adhesive PET material high temperature tape and Brown circuit board high temperature tape have lower continuous and peak temperature resistance values. This means that in a high - temperature environment like an EV battery during thermal runaway, these tapes may fail to maintain their structural integrity and performance, potentially allowing the spread of heat and flames.

5.2 Flame - Retardant Comparison

While some tapes may have some level of flame - retardant properties, Gold Finger Electronics Polyimide Tape Kapton's UL 94 V - 0 certification sets it apart. Self - adhesive back blocking spray paint tape and Brown circuit board high temperature tape may not meet the same strict flame - retardant standards. In a fire situation, the lack of proper flame - retardant properties in these tapes can lead to a faster spread of flames, increasing the risk of a major fire incident.

5.3 Chemical Resistance Comparison

Battery electrolytes can have a corrosive effect on tapes. Gold Finger Electronics Polyimide Tape Kapton's superior chemical resistance ensures that it can withstand the harsh chemical environment within an EV battery. In contrast, Self - adhesive back blocking spray paint tape and Brown circuit board high temperature tape may be more susceptible to chemical degradation, which can compromise their performance as firewalls over time.

6. Other Applications in EV Battery Systems

6.1 Insulation of Battery Cells

In addition to its role in battery firewalls, Gold Finger Electronics Polyimide Tape Kapton can be used for insulating battery cells. Its excellent electrical insulation properties prevent short - circuits between cells, which can also contribute to thermal runaway. By providing a reliable insulation layer, the tape helps to maintain the stability and safety of the battery system.

6.2 Protection of Battery Wiring

The tape can also be used to protect battery wiring. In an EV, the battery wiring is exposed to high currents and temperatures. Gold Finger Electronics Polyimide Tape Kapton's high - temperature resistance and electrical insulation properties make it an ideal material for safeguarding the wiring, preventing electrical malfunctions and potential fire hazards.

7. Manufacturing and Quality Assurance

7.1 Precision Manufacturing Process

Hunan Lvzhimei New Material Technology Co., Ltd., the manufacturer of Gold Finger Electronics Polyimide Tape Kapton, employs a precision manufacturing process. This process ensures that the tape meets the highest quality standards, with consistent thickness, adhesion, and performance characteristics. Advanced manufacturing techniques are used to produce the tape, guaranteeing its reliability in critical applications such as EV battery firewalls.

7.2 Quality Control Measures

To ensure the quality of the tape, strict quality control measures are implemented. These measures include testing the tape's physical properties, such as its tensile strength, adhesion, and heat resistance, as well as its chemical resistance and flame - retardant properties. Each batch of tape is thoroughly tested to ensure that it meets the required specifications before being released for use in EV battery systems.

8. Future Outlook and Industry Impact

8.1 The Growing Demand for EV Safety

As the demand for electric vehicles continues to grow, so does the need for enhanced battery safety. Gold Finger Electronics Polyimide Tape Kapton is well - positioned to meet this demand, offering a reliable and effective solution for EV battery firewalls. Its use in EVs is likely to increase in the future, as manufacturers seek to improve the safety and performance of their vehicles.

8.2 Potential for Further Innovation

There is also potential for further innovation in the development of Gold Finger Electronics Polyimide Tape Kapton. Researchers are constantly exploring ways to improve its performance, such as enhancing its heat resistance, flame - retardant properties, and chemical resistance. Future versions of the tape may offer even better protection for EV battery systems, contributing to the overall advancement of the EV industry.

9. Conclusion

Gold Finger Electronics Polyimide Tape Kapton is the ideal choice for electric vehicle battery firewalls due to its exceptional high - temperature resistance, UL 94 V - 0 certification, and chemical resistance. Its integration in vehicles like the Tesla Cybertruck has demonstrated its ability to delay thermal runaway and enhance battery safety. Compared to Self - adhesive back blocking spray paint tape and Brown circuit board high temperature tape, it offers superior performance in terms of thermal, flame - retardant, and chemical resistance. With the growing demand for EV safety and the potential for further innovation, Gold Finger Electronics Polyimide Tape Kapton is set to play an increasingly important role in the future of the electric vehicle industry. If you want to learn more about the applications of this tape in EV battery systems, you can download the technical whitepaper available at [download link]. This whitepaper provides in - depth technical details and case studies for a more comprehensive understanding.

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT