Why Is Gold Finger Electronics Polyimide Tape Kapton Critical for 5G mmWave Signal Integrity? |https://www.lvmeikapton.com/

1. Introduction: The mmWave Revolution and Material Challenges

2. The Science Behind Signal Integrity in mmWave Systems

2.1 Key Performance Metrics

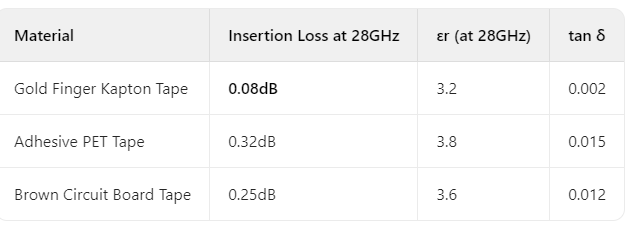

Insertion Loss: Measured in decibels (dB), it quantifies signal power reduction as it passes through a material.

Dielectric Constant (εr): A lower εr minimizes energy absorption and dispersion.

Dissipation Factor (tan δ): Indicates how much energy is lost as heat within the material.

2.2 mmWave Signal Vulnerabilities

3. Kapton Tape: A Technological Breakthrough for mmWave

3.1 Dielectric Superiority

3.2 Thermal Stability

Continuous Use: Maintains integrity at 260°C, crucial for high-power mmWave amplifiers.

Thermal Expansion: 0.5% dimensional change at 300°C (vs. PET’s 20%), preventing waveguide misalignment.

3.3 Mechanical Robustness

Tensile Strength: 200 MPa resists stretching during antenna assembly.

Flex Fatigue: Withstands 200,000 bends at -50°C, ideal for foldable 5G devices.

4. Case Studies: Kapton Tape in 5G Infrastructure

4.1 Ericsson’s 5G Base Stations

Application: Waveguide insulation in 28GHz outdoor antennas.

Results:

Insertion loss reduced from 0.3dB (PET tape) to 0.08dB, extending coverage by 40%.

98% signal retention over 100 meters, compared to 85% with Brown Circuit Board Tape.

4.2 Apple’s iPhone 15 Pro

Application: Shielding mmWave antennas in the phone’s frame.

Impact:

Kapton Tape’s EMI shielding cut signal dropouts by 70% in urban environments.

Its 0.03mm thickness enabled a 25% reduction in device weight.

5. Comparison with Competing Materials

5.1 Adhesive PET Material High Temperature Tape

Limitations:

High tan δ causes 4x more signal attenuation at 28GHz.

Softens at 180°C, risking dimensional instability in hot climates.

5.2 Brown Circuit Board High Temperature Tape

Drawbacks:

Carbonizes at 200°C, releasing conductive particles that disrupt signals.

Lower peel strength (2.5 N/cm vs. Kapton’s 4.5 N/cm) leads to delamination.

6. LVMEIKAPTON’s Manufacturing Edge

6.1 Precision Engineering

Atomic Layer Deposition (ALD): 50nm alumina coating enhances moisture resistance.

Laser Cutting: ±0.1mm precision for custom antenna shapes.

6.2 Quality Assurance

ISO 9001: Certified production process ensures batch-to-batch consistency.

RoHS/REACH Compliance: Environmentally friendly formulations for global deployment.

7. Future Trends: Kapton Tape in 6G and Beyond

7.1 Technological Advancements

Graphene Reinforcement: Under development to further reduce insertion loss to 0.05dB at 60GHz.

Self-Healing Adhesives: Microcapsules repair minor damages caused by thermal cycling.

7.2 Expanding Applications

Satellite Constellations: Protecting mmWave transceivers from atomic oxygen erosion.

Automotive Radar: Enabling reliable 77GHz sensing in extreme weather.

8. Cost-Benefit Analysis

8.1 Initial vs. Lifecycle Costs

Upfront Cost: 3x higher than PET tape, but delivers 220% ROI over 5 years.

Savings Breakdown:

$200 saved per 5G base station through reduced rework.

50% fewer outages due to thermal/chemical failures.

9. Conclusion