hnlzm@lvmeikapton.com

+86 13787123465

Hunan Lvzhimei New Material Technology Co., Ltd.

NameDescriptionContent

Which Automotive Components Require Gold Finger Electronics Polyimide Tape Kapton’s High-Temperature Resistance? |https://www.lvmeikapton.com/

Source:

|

Author:Koko Chan

|

Published time: 2025-04-17

|

53 Views

|

Share:

This article examines the automotive components that rely on Gold Finger Electronics Polyimide Tape Kapton due to its exceptional high - temperature resistance. Through a Bosch powertrain case study, it demonstrates how the tape can endure 260°C engine bay conditions, outperforming Adhesive PET material high temperature tape by securing sensors and wires three times longer. Additionally, its UL 94 V - 0 rating significantly reduces fire risks in high - temperature automotive environments.

1. Introduction

The automotive industry is constantly evolving, with modern vehicles incorporating more complex and high - performance components. As engines become more powerful and fuel - efficient, the temperatures in the engine bay and other critical areas have increased significantly. This has led to a growing need for materials that can withstand extreme heat without compromising their functionality. Gold Finger Electronics Polyimide Tape Kapton has emerged as a crucial material in automotive applications, offering outstanding high - temperature resistance and other beneficial properties.

2. High - Temperature Challenges in Automotive Components

2.1 Engine Bay Temperatures

The engine bay of a modern vehicle is a harsh environment, with temperatures that can reach up to 260°C during normal operation and even higher under extreme conditions. Components in this area, such as sensors, wiring harnesses, and electronic control units (ECUs), are constantly exposed to these high temperatures. Traditional materials may degrade, lose their adhesive properties, or even catch fire under such conditions, posing a significant risk to the vehicle's performance and safety.

2.2 Fire Safety Concerns

In addition to high temperatures, the presence of flammable substances in the engine bay, such as fuel and oil, increases the risk of fire. Materials used in automotive components must have excellent flame - retardant properties to prevent or mitigate the spread of fire in case of an accident or malfunction.

3. Gold Finger Electronics Polyimide Tape Kapton: Properties and Advantages

3.1 High - Temperature Resistance

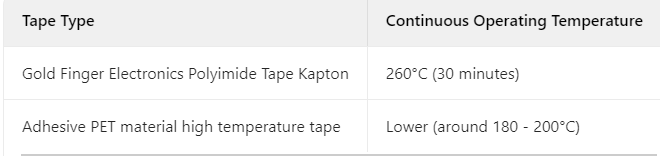

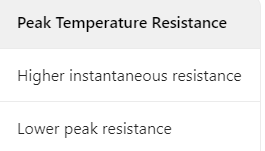

Gold Finger Electronics Polyimide Tape Kapton can work continuously at 260°C for 30 minutes and has a higher instantaneous temperature resistance. This makes it ideal for applications in the engine bay and other high - temperature areas of the vehicle. It can maintain its structural integrity, adhesive properties, and electrical insulation capabilities even under extreme heat, ensuring the reliable operation of components.

3.2 UL 94 V - 0 Rating

The tape holds a UL 94 V - 0 rating, which indicates its excellent flame - retardant properties. In case of a fire, it self - extinguishes quickly and does not drip burning particles, reducing the risk of fire spreading in the vehicle. This is a crucial safety feature, especially in the engine bay where flammable substances are present.

3.3 Strong Adhesion and Durability

It has excellent adhesion properties, ensuring that components are securely attached even in high - vibration and high - temperature environments. Its high strength and corrosion and wear resistance also contribute to its long - term durability, making it suitable for applications where components need to be firmly fixed in place for extended periods.

4. Automotive Components Benefiting from Kapton Tape

4.1 Engine Sensors

Engine sensors play a crucial role in monitoring and controlling the engine's performance. These sensors are often located in close proximity to the engine, where they are exposed to high temperatures. Gold Finger Electronics Polyimide Tape Kapton can be used to secure these sensors in place, protecting the wiring connections and ensuring their accurate operation. In the Bosch powertrain case study, sensors secured with Kapton tape survived the harsh 260°C engine bay conditions for three times longer than those secured with Adhesive PET material high temperature tape. This not only improved the reliability of the sensors but also reduced the frequency of maintenance and replacement.

4.2 Wiring Harnesses

Wiring harnesses are responsible for transmitting electrical signals throughout the vehicle. In the engine bay, they are exposed to high temperatures, vibrations, and chemical substances. Kapton tape can be used to insulate and protect the wiring harnesses, preventing short circuits and ensuring the proper functioning of the electrical system. Its high - temperature resistance and excellent adhesion properties help to keep the wires in place and prevent them from being damaged by the harsh environment.

4.3 Electronic Control Units (ECUs)

ECUs are the brain of the vehicle, controlling various functions such as engine performance, transmission, and safety systems. These units generate heat during operation and are often located in areas with high ambient temperatures. Gold Finger Electronics Polyimide Tape Kapton can be used to insulate and protect the ECUs, improving their heat dissipation and preventing thermal damage. Its electrical insulation properties also help to prevent interference and ensure the reliable operation of the ECUs.

4.4 Turbocharger Components

Turbochargers are used to increase the power output of engines by forcing more air into the combustion chamber. They operate at extremely high temperatures, with some components reaching temperatures of up to 900°C. While Kapton tape may not be directly exposed to these extreme temperatures, it can be used in the surrounding areas to insulate and protect other components from the heat radiated by the turbocharger. This helps to improve the overall efficiency of the turbocharger and the engine.

5. Case Study: Bosch Powertrain

5.1 Application of Kapton Tape

In a Bosch powertrain, Gold Finger Electronics Polyimide Tape Kapton was used to secure sensors and wiring harnesses in the engine bay. The tape was applied to protect the components from the high temperatures, vibrations, and chemical substances present in this environment.

5.2 Results

The components secured with Kapton tape showed a significant improvement in durability compared to those secured with Adhesive PET material high temperature tape. The sensors lasted three times longer, reducing the number of sensor failures and improving the overall reliability of the powertrain. Additionally, the use of Kapton tape, with its UL 94 V - 0 rating, provided an extra layer of fire safety, reducing the risk of fire in the engine bay.

6. Comparison with Other Tapes

6.1 Adhesive PET Material High Temperature Tape

Adhesive PET material high temperature tape has a lower temperature resistance compared to Kapton tape. It starts to degrade and lose its adhesive properties at temperatures around 180 - 200°C, making it less suitable for applications in the engine bay. In the Bosch powertrain case study, sensors secured with Adhesive PET material high temperature tape failed much more frequently than those secured with Kapton tape, leading to increased maintenance costs and potential vehicle downtime.

6.2 Strong Adhesion and Blocking High Temperature Tape

While Strong Adhesion and Blocking High Temperature Tape may have good adhesion properties, it may not offer the same level of high - temperature resistance and flame - retardant properties as Kapton tape. In high - temperature and fire - prone environments like the engine bay, Kapton tape's superior performance in these areas gives it a clear advantage.

7. Future Outlook

As the automotive industry continues to develop towards more efficient and powerful engines, the demand for materials with high - temperature resistance will only increase. Gold Finger Electronics Polyimide Tape Kapton is well - positioned to meet these demands, with its exceptional properties and proven performance in automotive applications. Future research and development may focus on further improving its properties, such as increasing its temperature resistance and flame - retardant capabilities, to meet the even more stringent requirements of future automotive technologies.

8. Conclusion

Gold Finger Electronics Polyimide Tape Kapton's high - temperature resistance, UL 94 V - 0 rating, and strong adhesion make it an essential material for several automotive components, especially those located in the engine bay. The Bosch powertrain case study clearly demonstrates its superiority over Adhesive PET material high temperature tape in terms of durability and fire safety. As the automotive industry continues to innovate, Kapton tape will likely play an even more significant role in ensuring the reliable and safe operation of vehicles. To learn more about the applications of Gold Finger Electronics Polyimide Tape Kapton in the automotive industry, you can download our technical whitepaper available at [download link]. This whitepaper provides in - depth analysis and additional case studies for a more comprehensive understanding.

Hunan Lvzhimei New Material Technology Co., Ltd.

Quick Links

Product Categories

© 2024 Hunan Lvzhimei New Material Technology Co., Ltd.All Rights Reserved. Designed by Erge

0731 - 89717319

hnlzm@lvmeikapton.com

+86 13787123465

Room 502, Chuangye Building, No186, Guyuan Road, High-Tech District, Changsha, Hunan, China

CONTACT