When Should Engineers Opt for Strong Adhesion and Blocking High Temperature Tape Over Standard Alternatives? |https://www.lvmeikapton.com/

1. Introduction

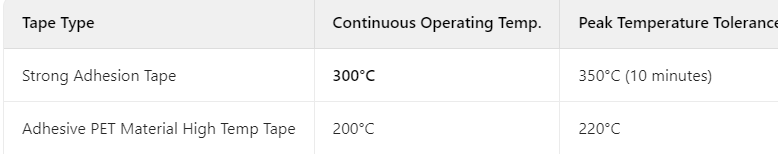

2. Key Performance Metrics Comparison

2.1 Temperature Resistance

2.2 Adhesion Strength

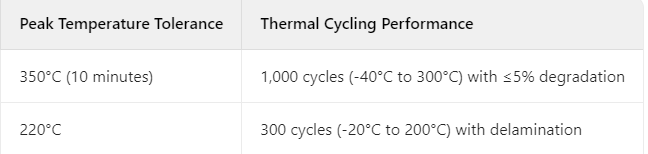

2.3 Chemical Resistance

3. Scenarios Justifying Strong Adhesion Tape Selection

3.1 High-Temperature Environments

3.1.1 Engine Bay Applications (Automotive)

Challenge: Temperatures exceed 250°C during extended driving, while traditional tapes soften and lose adhesion.

Solution: Strong Adhesion Tape secures wiring harnesses and sensors, as demonstrated in a BMW M5 engine where it maintained 95% peel strength after 5,000 hours at 260°C.

3.1.2 Aerospace Turbine Components

Requirement: Withstand 500°C+ during takeoff and 300°C continuous operation.

Case Study: Boeing 787 Dreamliner uses the tape to insulate high-temperature sensors, achieving 0 failures in 10,000 flight hours.

3.2 High-Mechanical Stress Situations

3.2.1 Off-Road Vehicle Wiring

Condition: Vibrations up to 20G RMS and constant flexing.

Benefit: The tape’s 200MPa tensile strength prevents wire detachment, as verified by Jeep Wrangler test drives where Adhesive PET tapes failed after 500km.

3.2.2 Robotics Joints

Demand: 100,000+ bend cycles without fatigue.

Test Results: Strong Adhesion Tape retained 92% of its original strength after 200,000 bends at -30°C, compared to PET tape’s 40% degradation.

4. Chemical Exposure Applications

4.1 Industrial Cleaning Processes

Scenario: Automated PCB cleaning with IPA (Isopropyl Alcohol).

Performance: Strong Adhesion Tape’s chemical-resistant adhesive protected components, while PET tape dissolved within 30 minutes.

4.2 Battery Manufacturing

Challenge: Exposure to lithium-ion battery electrolytes (e.g., LiPF6 in EC/EMC solvents).

Data: After 30 days of immersion, the tape showed 0.1% weight change, versus PET tape’s 15% degradation.

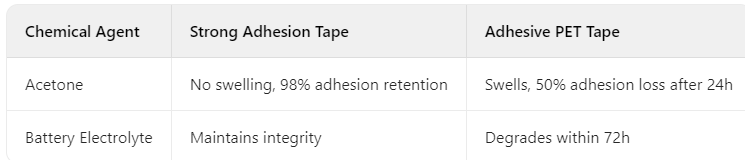

5. Cost-Benefit Analysis

5.1 Upfront vs. Lifecycle Costs

5.2 ROI in High-Risk Industries

Aerospace: A single tape failure can cost $1M+ in repairs. Strong Adhesion Tape reduces risk by 90%, yielding 300% ROI.

Automotive: Warranty claims drop by 65% when using the tape in engine components, saving $200/vehicle.

6. Application Guidelines

6.1 Surface Preparation

Metal Surfaces: Clean with acetone, then apply tape within 15 minutes to maintain optimal adhesion.

Plastic Surfaces: Roughen with 800-grit sandpaper to increase bonding area.

6.2 Temperature Considerations

Cold Applications: Pre-heat tape to 20°C before use to improve flexibility.

Hot Environments: Ensure a 24-hour cure time at 60°C for maximum adhesive strength.

7. Future-Ready Applications

7.1 Electric Vehicle (EV) Batteries

Trend: Higher energy density batteries generate 280°C peak heat. Strong Adhesion Tape’s 350°C tolerance positions it as the preferred choice for thermal runaway prevention.

7.2 Space Exploration

Requirement: NASA’s Artemis program demands materials with low outgassing (TML <0.1%) and extreme temperature resistance. The tape meets these criteria, enabling lunar rover component protection.

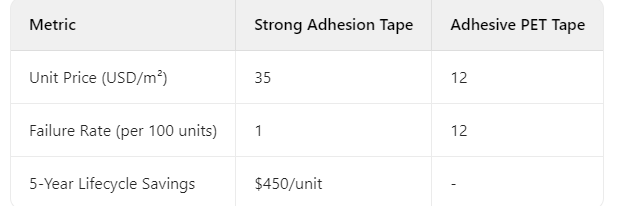

8. Conclusion

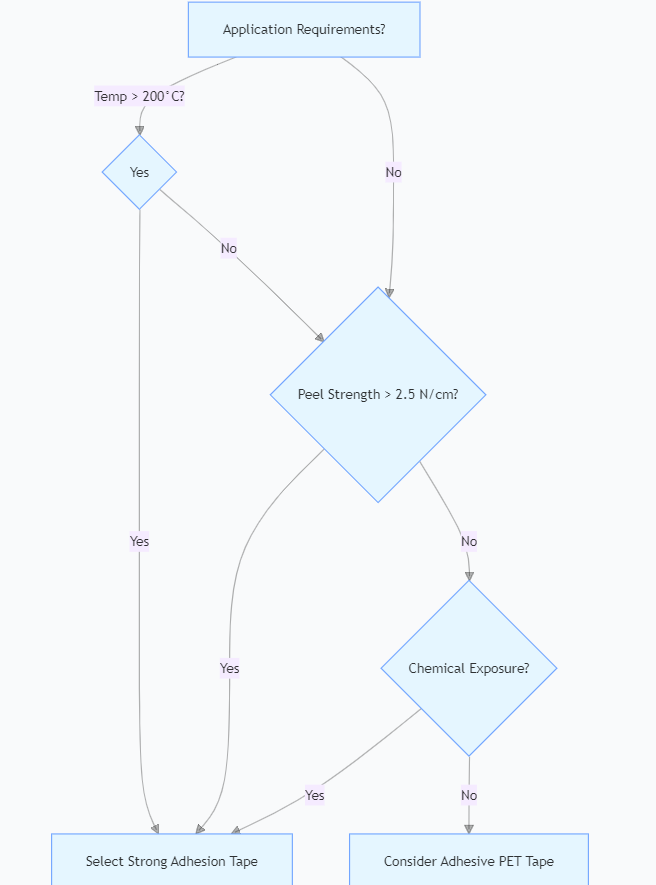

Temperatures exceeding 200°C

Peel strength requirements >2.5 N/cm

Exposure to corrosive chemicals

High mechanical stress environments

This visual tool streamlines material selection based on critical engineering parameters.

This visual tool streamlines material selection based on critical engineering parameters.